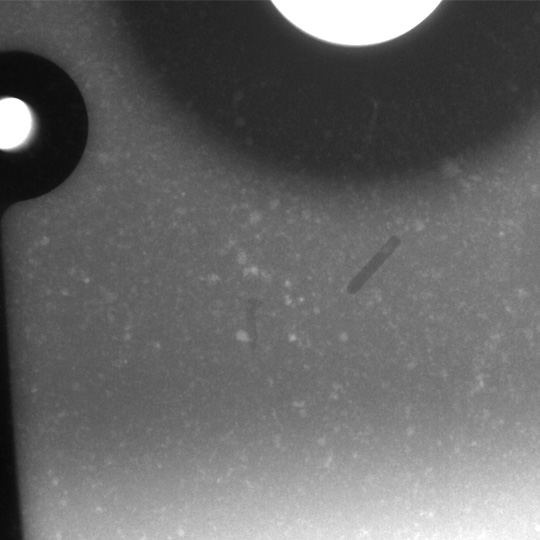

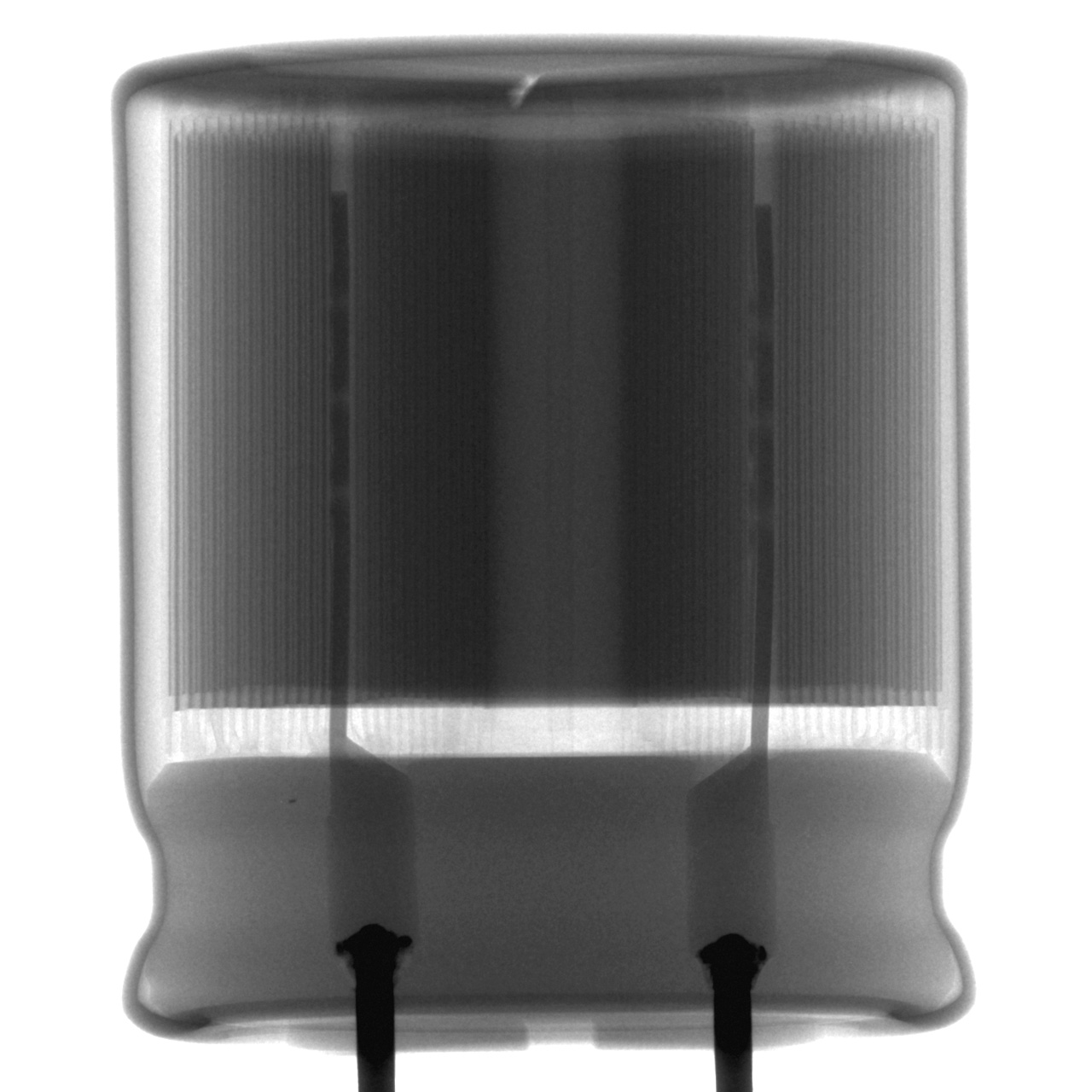

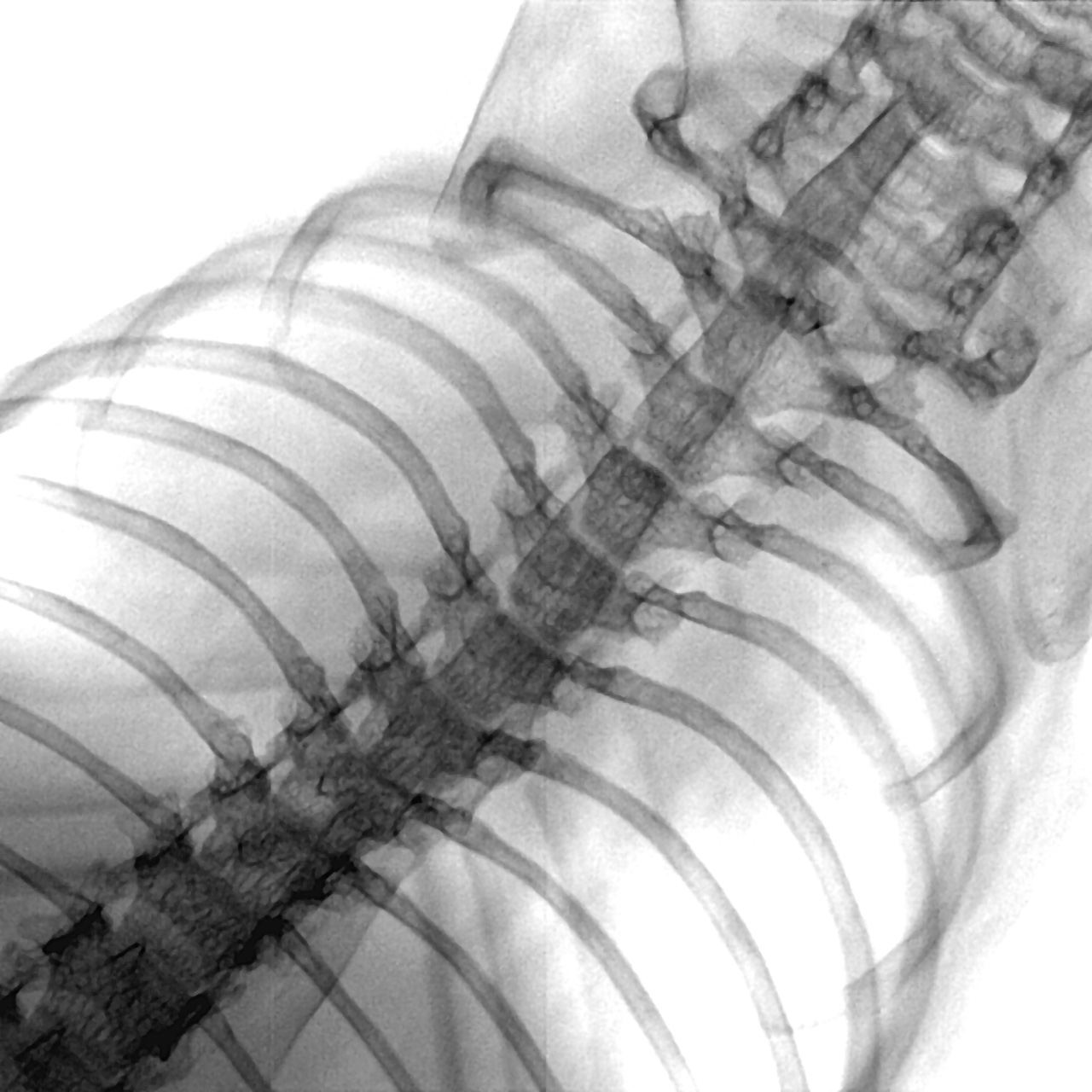

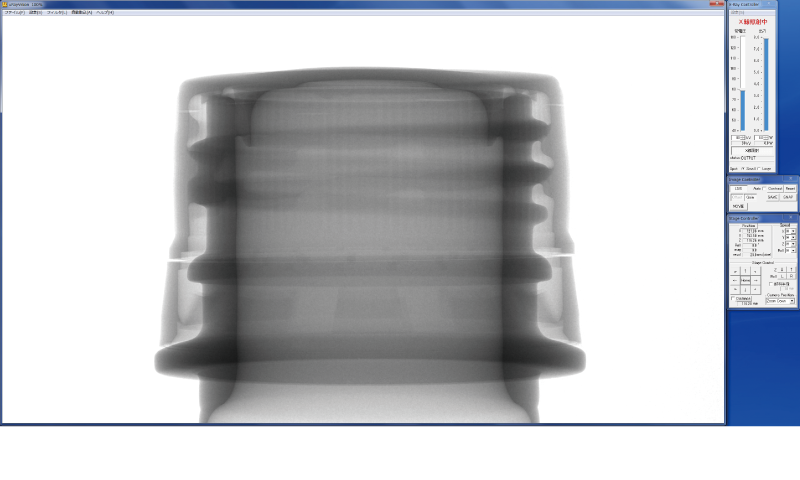

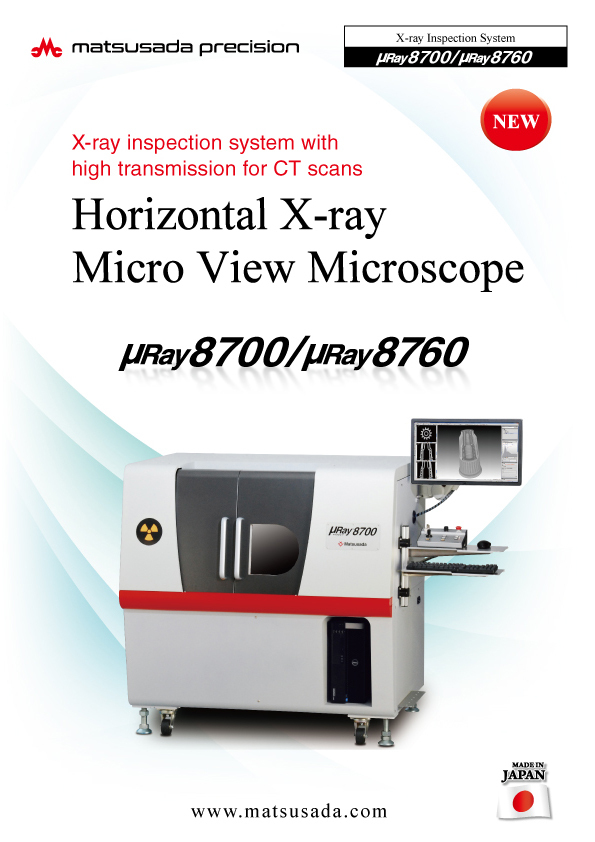

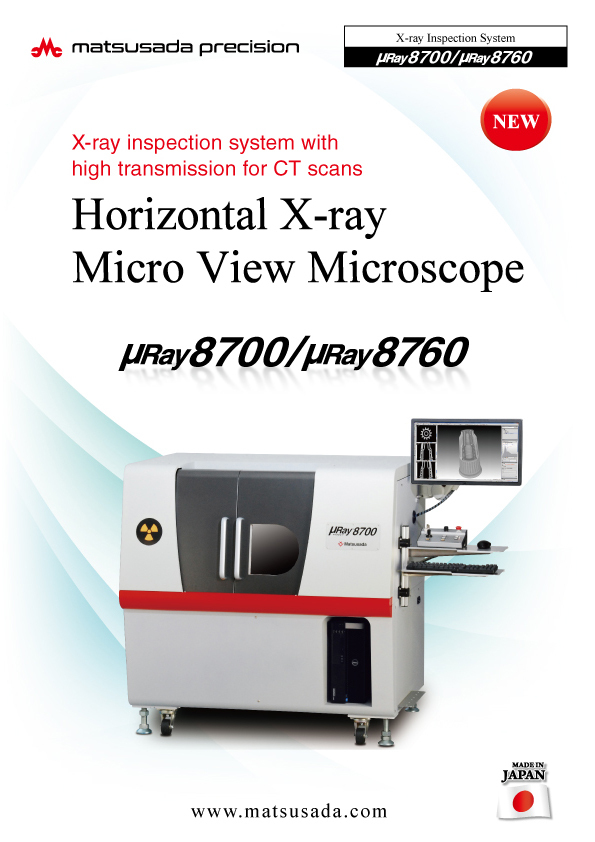

The µRay8700/µRay8760 is a micro CT system covering small to large object sizes. High-power microfocus X-rays of 130kV and 40W provide high-definition images with low noise and 3D images with high spatial resolution.

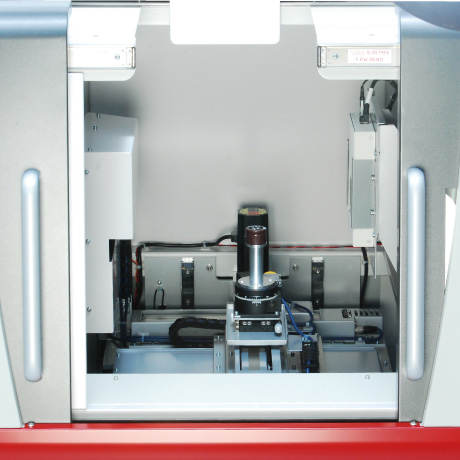

Transmission inspection of object longitudinal cross section is easy with horizontal X-ray radiation type

In addition to the X-axis (left/right), Y-axis (front/rear), and Z-axis (up/down), it also has a rotation axis (turn), which enables observation of the entire object.

A roundwork can be easily observed by placing it on the stage and turning it 360 degrees. The stage can be moved to the left/right, front/back, and up/down, allowing for easy operation.

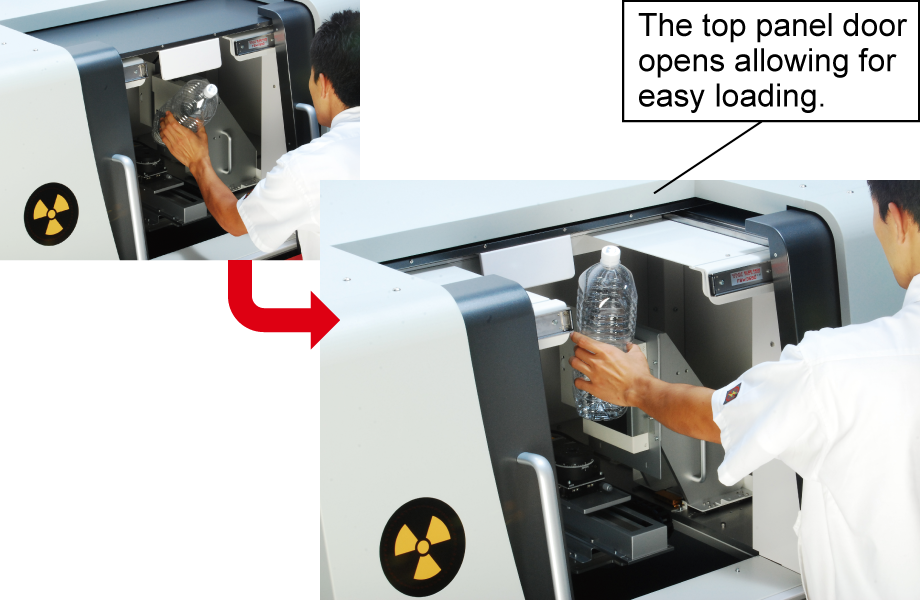

As the top panel door opens, a long or heavy work (10 kg) can easily be loaded on the stage.

* The door of the ceiling is not attached in μRay8760

* The durable supporting weighting 10 kg is optional.

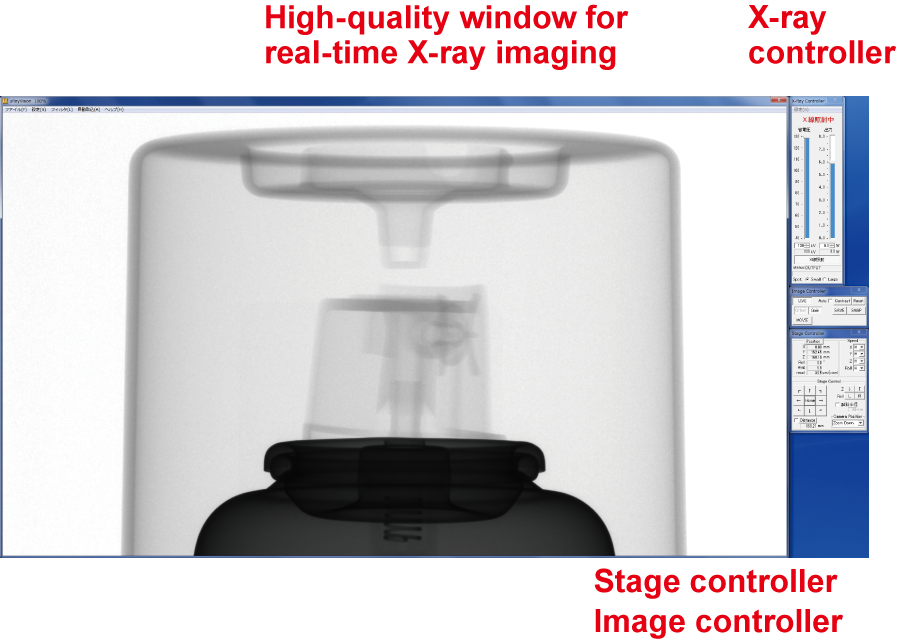

Software [µRay®Vision]

Simple operation allows for the use of necessary functions by "anyone" "in no time".

The accompanying dedicated software, "µRay®Vision", not only allows for stage control and simple X-ray operation but also features a variety of image processing and measurement functions.

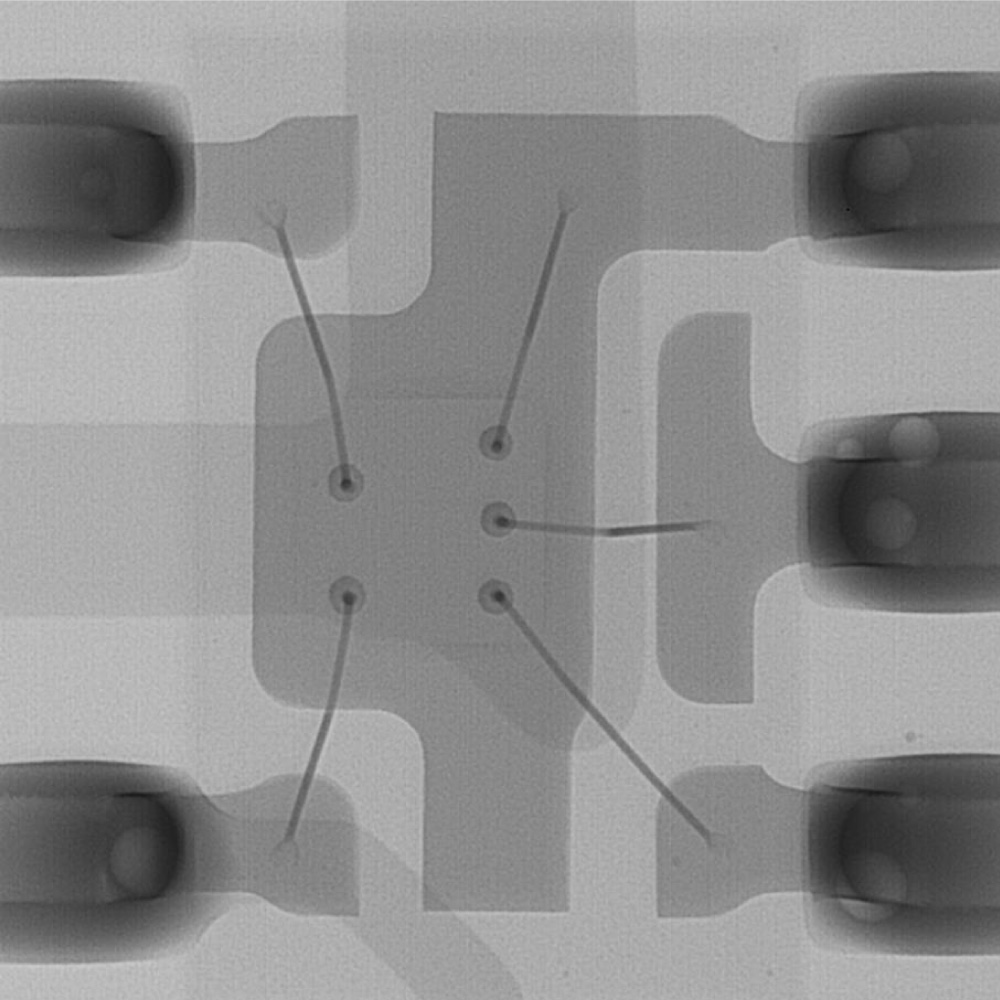

Simple observation and analysis

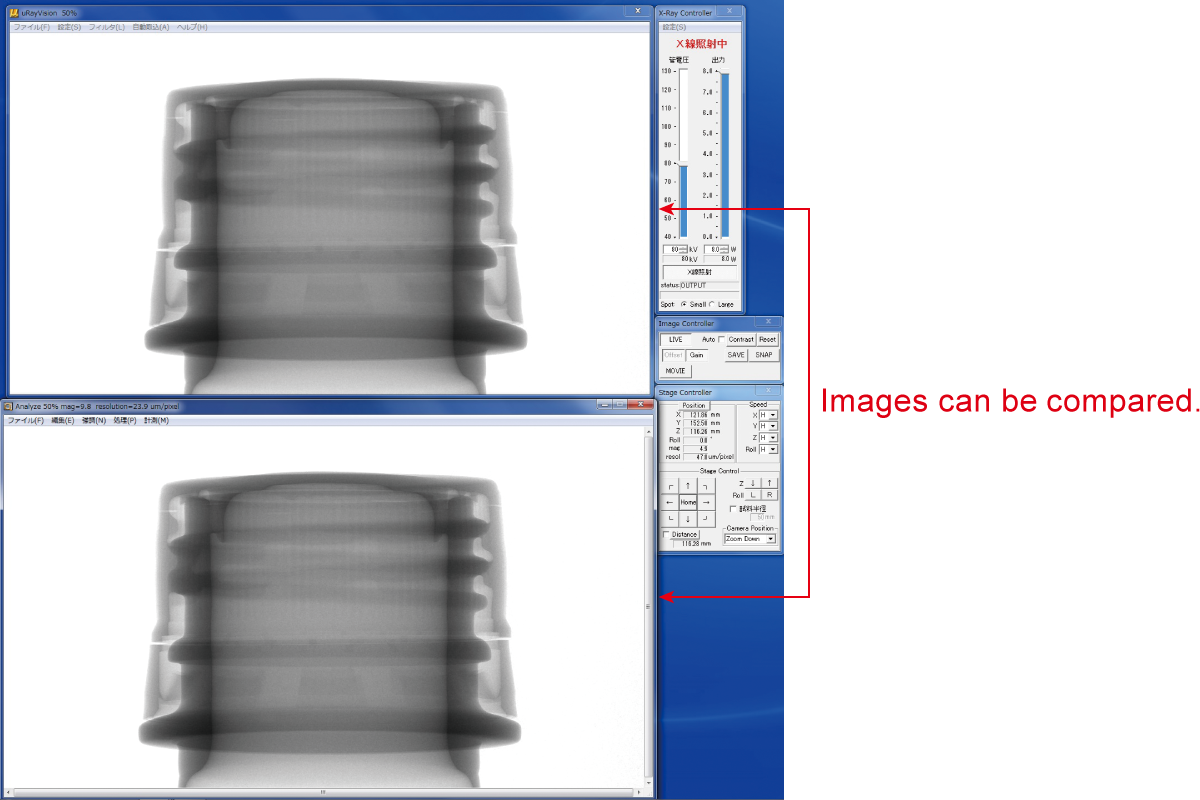

With the reduced display function, you can easily make comparative observations.

By switching from the high-resolution display to the reduced display, you can perform observation/analysis of the sample by comparing it with previously saved images.

Easy operation for image processing and analysis

With the exclusive software as standard, advanced image processing and analysis are available in simple operations

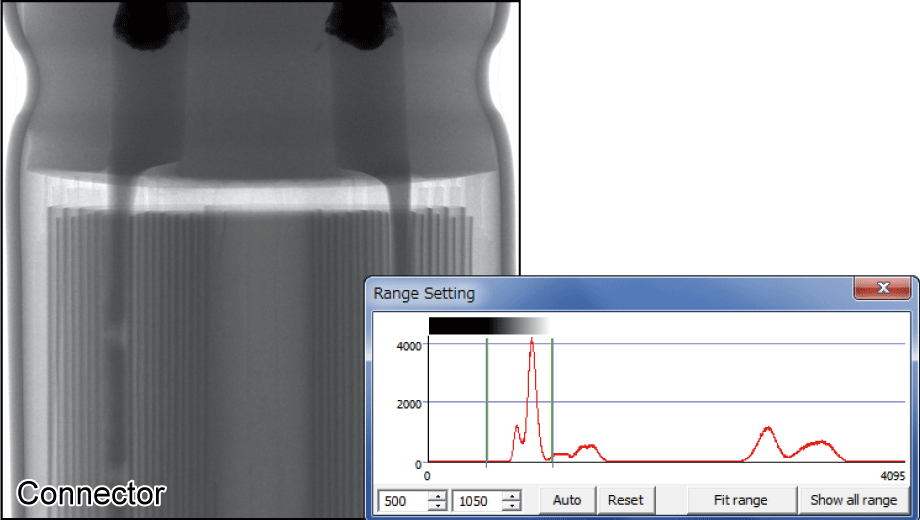

Display range

Allows you to set an arbitrary gray level based on an image's histogram and then enhance the contrast manually.

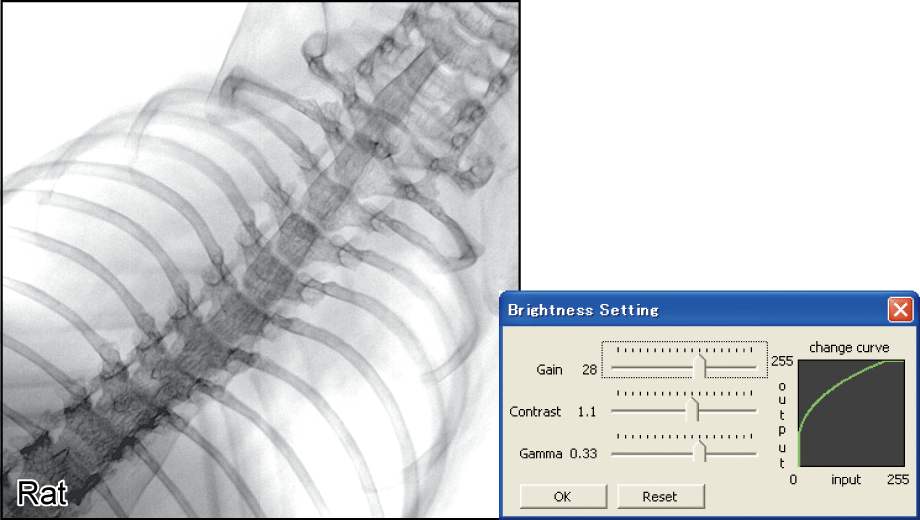

Brightness control

Individually controlling the gain, contrast, and gamma values allows for a flexible change of the brightness value of images.

Datasheets

If you are unable to download a file

Please try the following solution.

- Please press Ctrl+F5 to clear the cache of your web browser and try again.

- Please restart your web browser and log in again to try again.

- Please change your web browser to another browser and try again.

- Restart the computer and try again.

- Please try again on a different computer.

-

-

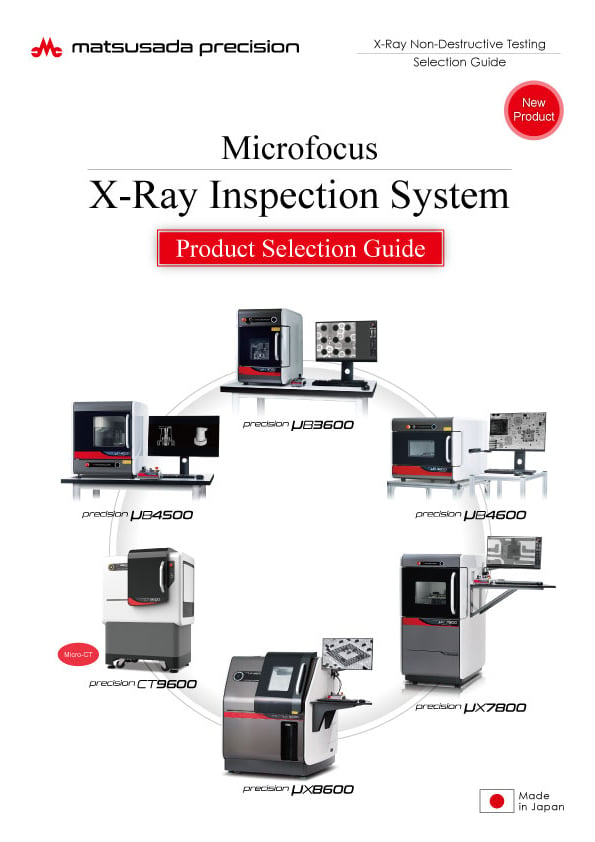

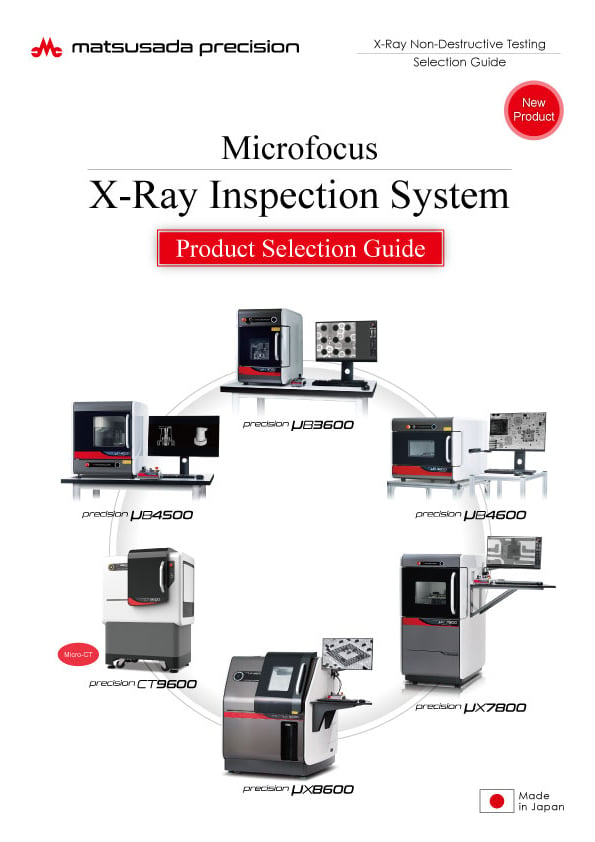

Microfocus X-Ray Inspection System Selection Guide

Date: 2025-01-30 rev.05

Click here

PDF (13,817 KB) -

Login Required

-

µRay8700/µRay8760 Datasheet

Date: 2024-01-09 Rev.06

PDF (3,836 KB) -

Microfocus X-Ray Inspection System Selection Guide

Date: 2025-01-30 rev.05

PDF (13,817 KB) -

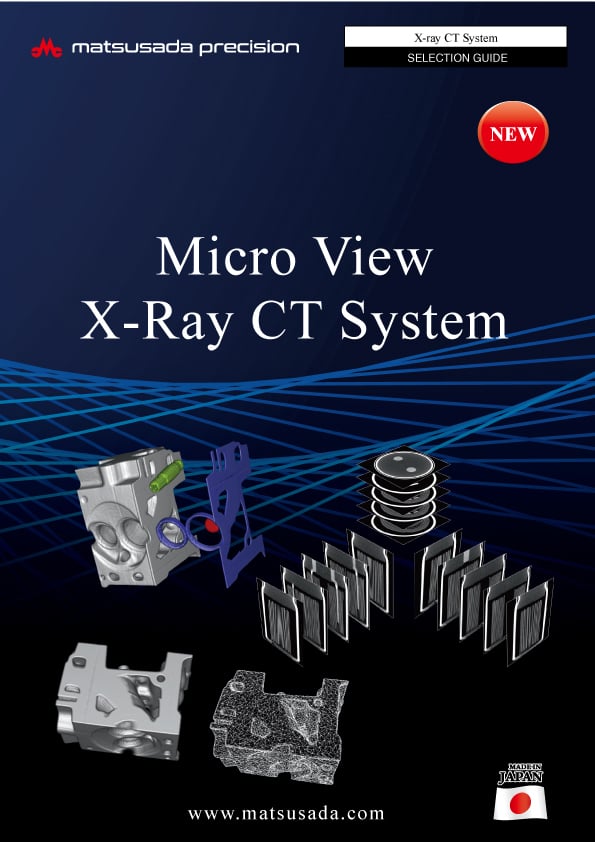

Micro View X-Ray CT System Guide

Date: 2024-12-26 Rev.07

PDF (9,615 KB)

Information on related articles in Technical Knowledge

Similar products

-

New

precision CT9600

- X-ray tube voltage

- 130kV

- X-ray power

- 40W

X-ray Micro-CT Scanner -

New

precision μX8600

- X-ray tube voltage

- 130kV

- X-ray power

- 40W

Microfocus X-Ray Inspection SystemTop and Oblique Angle View

-

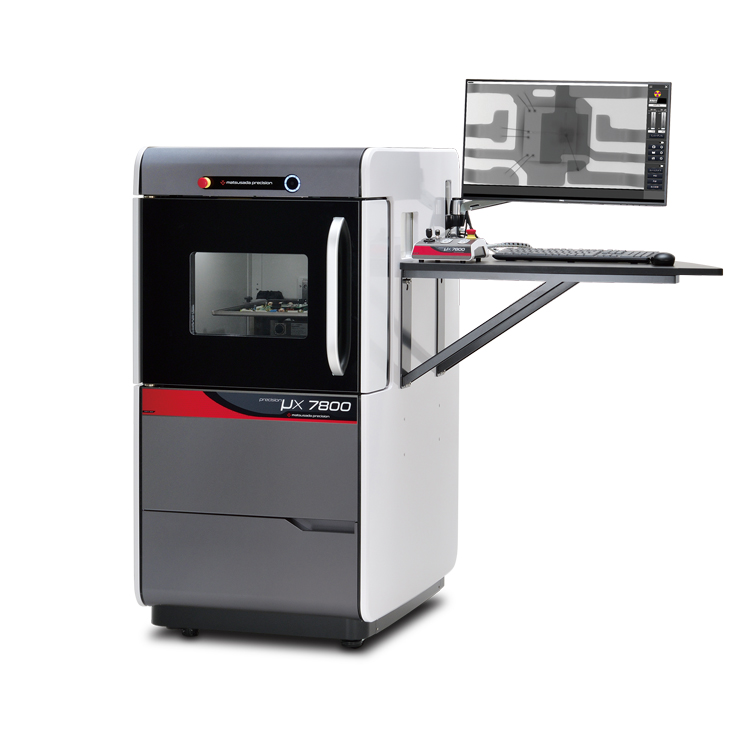

precision μX7800

- X-ray tube voltage

- 90kV

- X-ray power

- 18W

X-ray Inspection SystemAll-round Model

-

μRay8400

- X-ray tube voltage

- 130kV

- X-ray power

- 40W

130kV micro focus X-raySuitable for observing large footprint material or specimens