Microfocus X-ray

Inspection System

[μRay8600]

Matsusada Precision product µRay8600 series - With a 130kV microfocus X-ray tube, the X-ray inspection system offers high transmission observations for aluminum die casting, forged products, and metal parts.

The μRay8600 is no longer available as we stopped the production and sales of this model in January 2025. Meanwhile, we support.

precision μX8600 is available as the successor model, and more information on the series can be found here.

Advanced X-ray inspection system best for thick object observation

With a 130kV microfocus X-ray tube, the X-ray inspection system offers high transmission observations to aluminum die casting, forged products, and metal parts. The X-ray system is also suited for non-destructive inspections of welding defects and is used for Printed Circuit Board Assembly Inspection to power devices and heat sinks. Using the tiltable X-ray camera, you can easily observe three-dimensionally BGA joints and other defects that cannot be seen directly above. Furthermore, the combination of a high-power microfocus X-ray source and a high-resolution flat-panel detector offers high-resolution and clear X-ray images. The X-ray system is available in a wide range of applications, from product development and quality evaluation analysis to inspections at worksites.

Features and Benefits

- Maximum 130kV X-ray tube for high-transmission imaging

- Tiltable camera for three-dimensional observation

- Increasing magnification by microfocus X-ray source

- High-resolution flat panel detector for high-quality X-ray image

- Easy-to-use software

- CT scanning (option)

Datasheets

If you are unable to download a file

Please try the following solution.

- Please press Ctrl+F5 to clear the cache of your web browser and try again.

- Please restart your web browser and log in again to try again.

- Please change your web browser to another browser and try again.

- Restart the computer and try again.

- Please try again on a different computer.

-

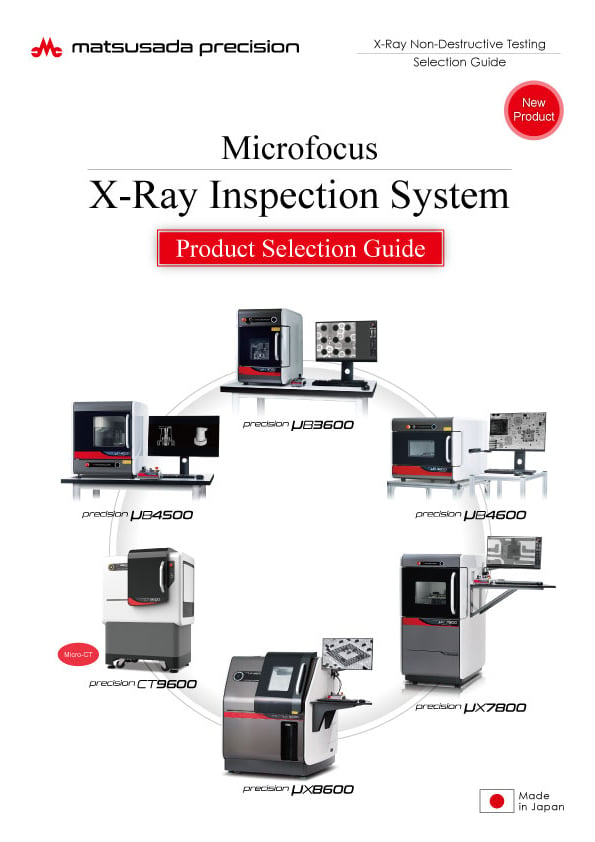

Microfocus X-Ray Inspection System Selection Guide

Date: 2025-01-30 rev.05

Click here

PDF (13,817 KB) -

Login Required

-

Microfocus X-Ray Inspection System Selection Guide

Date: 2025-01-30 rev.05

PDF (13,817 KB) -

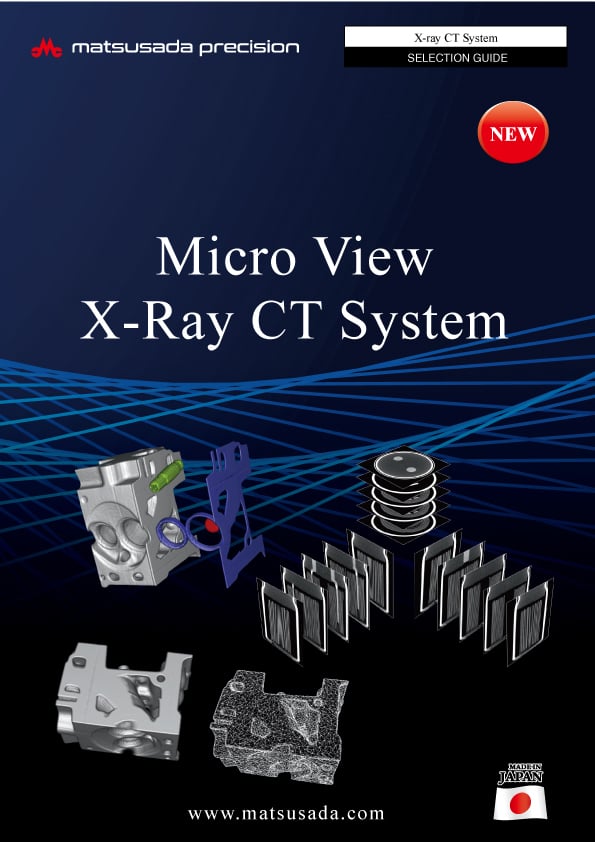

Micro View X-Ray CT System Guide

Date: 2024-12-26 Rev.07

PDF (9,615 KB)

Information on related articles in Technical Knowledge

Similar products

-

New

precision μX8600

- X-ray tube voltage

- 130kV

- X-ray power

- 40W

Microfocus X-Ray Inspection SystemTop and Oblique Angle View

-

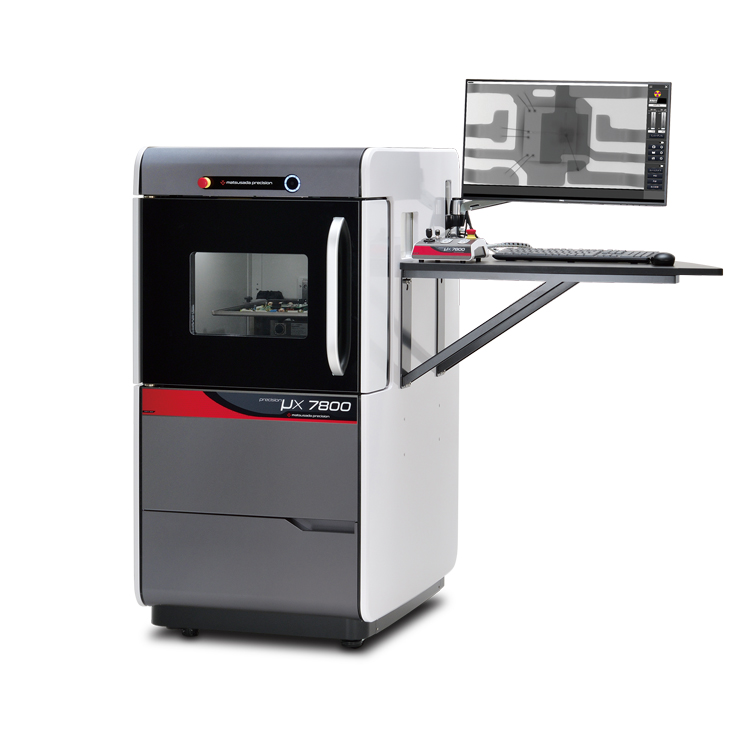

precision μX7800

- X-ray tube voltage

- 90kV

- X-ray power

- 18W

X-ray Inspection SystemAll-round Model

-

New

precision CT9600

- X-ray tube voltage

- 130kV

- X-ray power

- 40W

X-ray Micro-CT Scanner -

New

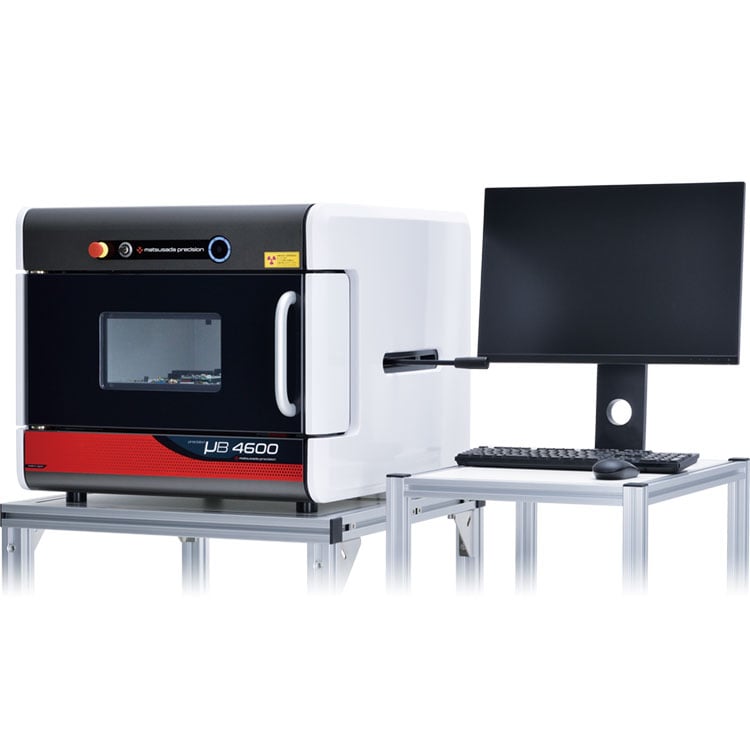

precision µB4600

- X-ray tube voltage

- 60 to 90kV

- X-ray power

- 9 to 60W

X-ray Inspection systemHigh Power Model