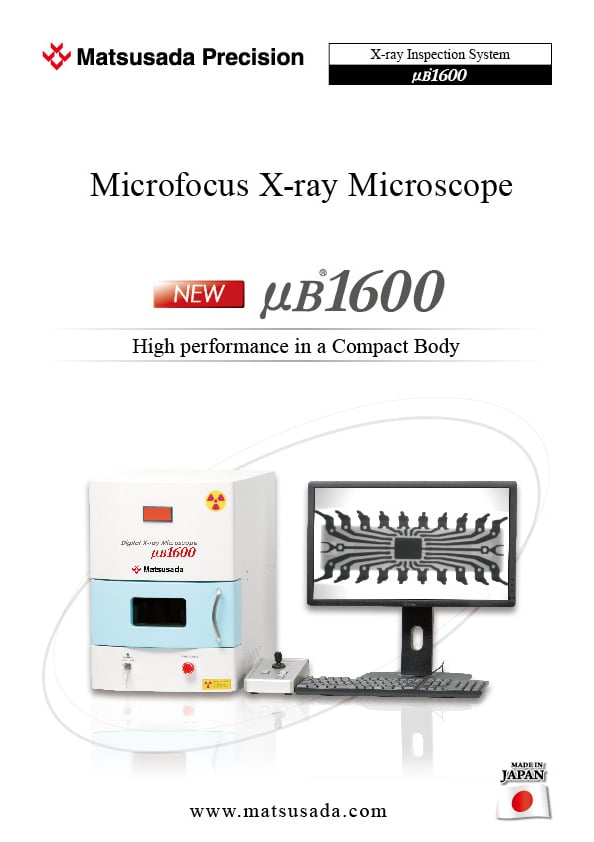

Microfocus X-ray

Microscope

- X-ray Voltage:

20 kV to 60 kV - Microfocus x-ray tube

High performance in a Compact Body

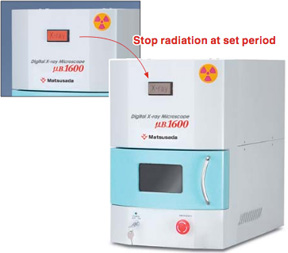

As a leading manufacturer of high-voltage power supplies that have supported the cutting-edge area of X-ray inspection systems, semiconductor manufacturing, and medical devices. We are proud to introduce the µB1600, a micromini model of micro-focus X-ray inspection system. The µB1600 has an internal micro-focus X-ray source and high-resolution X-ray camera, and can perform transmission imaging and measurements regardless of installation locations.

Features and Benefits

Hardware

- Microfocus x-ray tube

- Digital imaging camera

- 4.7 inches x 4.7 inches area stage

- X-Y shifting stage

- Rotating stage

- Joystick controller

- Low-leakage x-ray dose (less than 1 µSv/hr)

- Safety functions: interlock, emergency stop and so on

Software

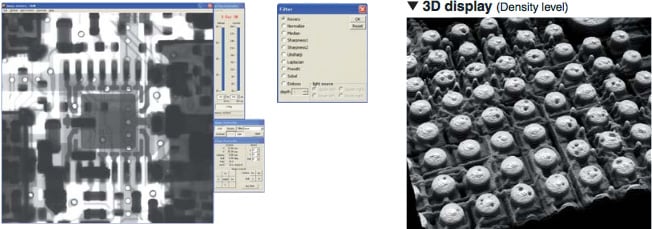

- 12 bit density resolution

- Density processing: three dimension (3D), pseudo color, pseudo stereo and so on

- Intensity processing: brightness, contrast, non-linear contrast stretch (gamma), filtering, inverting, binary, histogram and so on

- Measuring functions: distance, angle and area

Applications

- Composites, ceramics and plastics

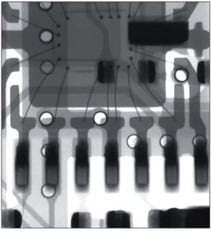

- Electronic and electrical components

- Populated and unpopulated Pcb's

1. Futuristic Technology Integration

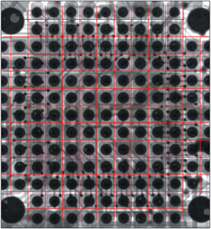

The best images produced by state-of-the-art technology of X-ray and FPD

Matsusada Precision's original technology detects the subtlest contrasting density of specimens that can not be detected by conventional devices. Additionally, the FPD built in the µB1600 provides even images with no distortion.

2. Anyone can master the µB1600 quickly!

Optimal conditions are automatically set

All an operator has to do is set a specimen and emit the X-ray. The µB1600 adjusts the contrast automatically and shoots the specimen under optimal conditions.

3. Multifunctional but easy to operate

Various image processing and measurement software are included as standard equipment

The µB1600 has massive functions that can be used as an analytical device, a matter of course, also as an inspection machine. The µB1600 is easy to use. Even a first-timer can operate µB1600 smoothly.

Leading Edge Technology in compact body

World's FirstMicro-focus X-ray

The µB1600 has an internal micro-focus X-ray source creating ultra-high image quality in spite of its compact size. The integration of 60kV and 150µA X-ray tube and Matsusada Precision's high-voltage technique has succeeded in developing a small-sized and high-performance X-ray generator.

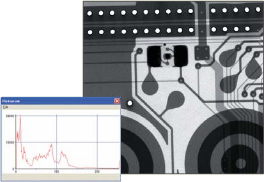

Digital X-ray camera

A digital X-ray camera with a flat panel is used in the imaging part. The high-resolution camera with one million pixels of 1024 ×1024 clearly detects an object aimed at. Images with no distortion in every detail can be obtained.

14bit digital data

High-definition data with 1.5 million pixels are imported by 14-bit. The images can be processed and analyzed flexibly afterward.

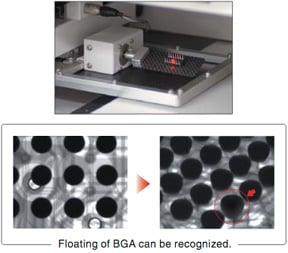

High-precision stage

The series has the rotatable stage along with the three axes of X, Y axes and variable enlargement ratio axis, enabling transmission from any angle. Moreover, it meets your needs for more detailed imaging for smaller parts. It can also detect floating BGAs.

Model

| Model | X-ray Source | Imaging Section | Stage | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Anode voltage | Anode current | Focal size | Size of visual field | Number of valid pixel | Density resolution | Monitor | Lower and upper imaging part Stroke | Sample platform | XY Stroke | Rotation Stroke | Shifting operation | ||

| Size | Load capacity | ||||||||||||

| μB1600 | 20 kV to 60 kV | 150 µA MAX | 5 µm | 2.52 inches (64 mm) x 2.24 inches (57 mm) | 1.5 M pixels | 14-bit | 24 inches | 7.87 inches (200 mm) | X 4.72 x Y 4.72 inches (X 120 x Y 120 mm) |

1kg | X 4.72 x Y 4.72 inches (X 120 x Y 120 mm) |

360° (manual) | Direction indication by mouse, Joystick can be used together. |

| Geometric image magnification | 11 to 19.8 times |

|---|---|

| Monitor magnification | 60 to 100 times |

| Field of view | 0.16 x 0.20 inches (3.2 x 3.6 mm) to 0.24 x 0.28 inches (5.0 x 6.0 mm) |

| Input voltage | 100 Vac 50/60 Hz * |

| Dose of X-ray leakage | less than 1 µSv/hr |

* The other voltage is selectable. Please ask the sales department.

Functions

Ultimate Operability

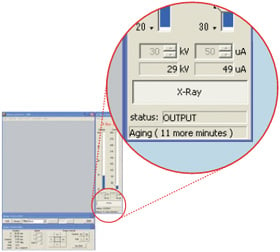

Automatic conditioning function

Dates when the µB1600 were used are memorized. The conditioning process is automatically selected based on how many hours have passed since that day to ensure optimum conditioning. (In the operating software, this is referred to as "Aging.")

Note: Proper conditioning and operation can significantly extend the life of x-ray tubes.

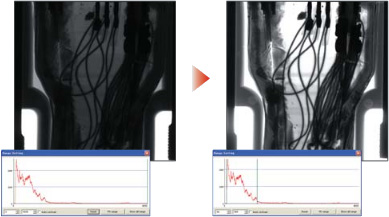

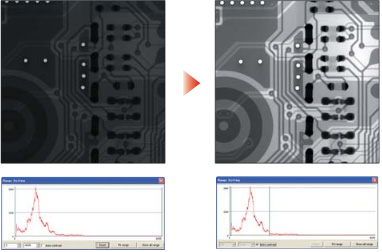

Auto contrast adjustment function

Images shot by 12bit are displayed in optimal gradation sequence. Variations by photographers (e.g., dark images, whitish images, etc) can be eliminated to always display optimally. Even a first-timer does not miss the points that he or she wants to observe. It is also possible to display any given tonal range.

Automatic shutoff function

In some cases, people apply themselves to analyzing images and forget to turn off the X-ray. The automatic shutoff function turns off the X-ray automatically by setting the time in advance. This function is also convenient in case an operator leaves the device.

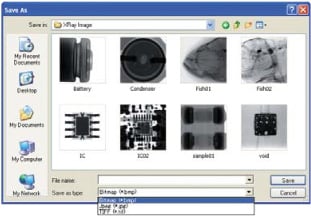

Data storage (bmp, jpg, tif)

Images both before and after analyses can be easily saved. Extensions including bmp, jpg, and tif can be selected depending on the extendability. Once saved data can be read out and analyzed repeatedly by the analysis software.

Smooth & Easy Operation even for first-timers

Image analysis

The brand new image analysis software dedicated for our x-ray inspection system can controls the stage and X-ray with easily operations and is equipped with various image processing and measurement functions.

Reduced display function

The moving image window displays not only high-resolution images with one million pixels but also reduced images allowing specimens to be inspected compared with the images on the static image window.

Filter function

The µB1600 supports ten or more types of filtering and image processing, allowing detailed image analyses. Images can be analyzed in real-time by performing appropriate filtering for displaying moving images.

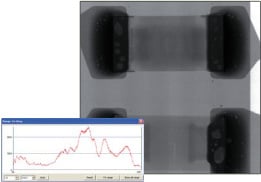

Image analyze window function variety

Display range window

The contrast can be enhanced manually by setting any given densities based on the histogram of shot images.

Brightness adjustment

Brightness values of shot images can be adjusted freely by adjusting gain, contrast and gamma values individually.

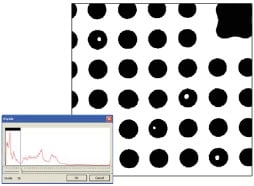

Histogram display

The µB1600 displays a histogram to indicate the distribution of brightness of shot images.

Binarizing processing

A shot image can be displayed in a binary manner by contrast by setting a threshold and binarizing the image.

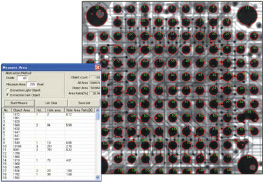

Area calculating

The µB1600 can measure the areas, number of holes, area of holes and area ratio of an object in a shot image.

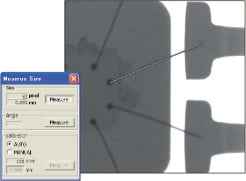

Size measurement

Sizes in a captured image can be measured by drawing measurement lines on the shot image.

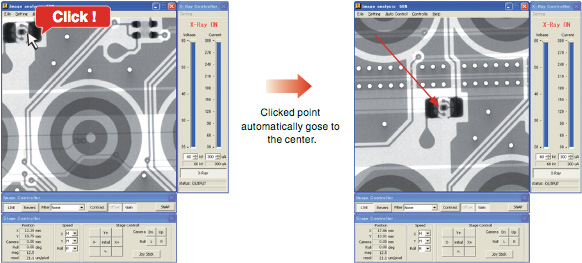

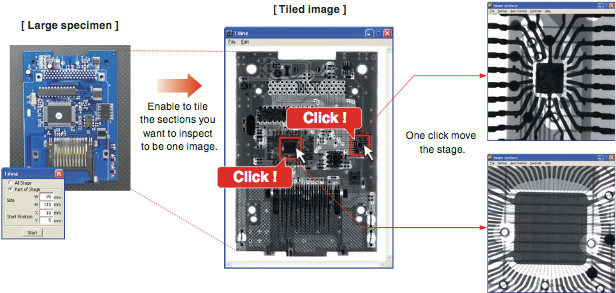

Shift by click

Click on an image, and quickly move to the location you want to observe.

In addition to normal stage operation, the clicked section becomes centered.

Interlink function

Interlink function realizes a piece of fluoroscopy image at maximum 4.72 inches × 4.72 inches for a large-sized specimen that can't be captured with one shot. Interlink function can also make a piece of fluoroscopy image of a large-sized specimen by specifying points. By shooting and saving an interlinked image once, you can use the automatic transfer function to move the stage to the clicked position from interlinked fluoroscopy images by just reading in an image. Interlink function realizes

Teaching function

The teaching function moves the stage automatically to the pre-registered points. This allows the system to "learn" problem areas and capture them on an X-ray image automatically. Setting X-ray output, enlargement factor and stop time, etc., for each point supports various test objectives. The teaching function moves the stage automatically to the pre-registered points. This allows the system to "learn"

For various applications

Electrical components

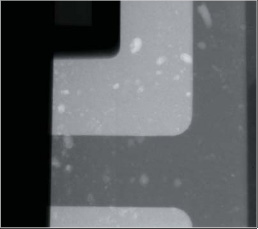

BGA

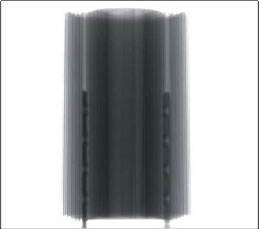

Capacitor

Liquid crystal device

Electrical components

Connector

Metal parts

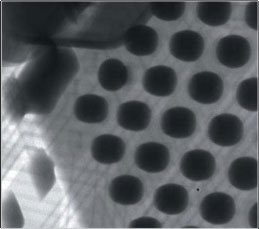

Holes in Aluminum sample

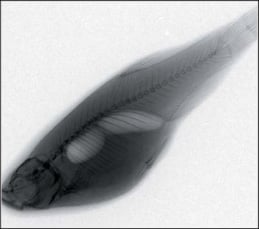

Biology

Fish

Various standard functions

Easy operations by joystick

The joystick allows easy movements of the stage along the X and Y axis, 360-degree rotation of the stage, and changes in image magnification.

Display the position of observing

The laser pointer indicates the center of the displayed image. It is possible to position by observing the sample.

Safety functions

- Low-leakage X-ray dose

- The operator needs no special licensing to operate the µB1600.

- Emergency Stop Function

- Pushing this button stops the x-ray and the stage from operating in an emergency situation.

- Interlock Function

- The X-ray will shut off the moment the door is opened.

Specifications

Accessories

- XDSK100

Aluminum table for option

- STG002

Height adjustment stage

-

Size: 120 mm × 120 mm

The stage helps you to raise its height. Therefore, the sample can be closer to the X-ray camera for shooting, so you can take larger field images.

Applications

Fields and Applications of X-ray Radiography Non-Destructive Testing

- Pharmaceuticals and Cosmetics

- Tablets, Capsules, Catheters, Medical pouches, Foreign objects in the face mask, Cosmetics

- Automobiles and Electric Vehicles

- Automotive components, Wire harness, Batteries, Molded plastic parts, Motor, Insert molded parts, Aluminum die casting, Sensor, Mating parts connection

- Electronics

- Ball grid array (BGA), Integrated circuit (IC) chip, Connectors, Capacitors, LED, Relays, Printed circuit board (PCB), AC adapter, Light bulbs filament, Electrical cable disconnects, Discharge traces of dielectric breakdown

- Advanced Materials

- Carbon-Fiber-Reinforced Polymers (CFRP), Insulation material, Carbon, Dissimilar material joint, Contamination in beryllium

- Precision Conponents

- Probe, Bearing, Mating of plastic parts, Spring position

- Creatures and Plants

- Laboratory rats, Seeds, Flowers, Shell, Bone, Insects, Rice

- Others

- Microscopic foreign matter contamination, Voids in welding, Plastic bottle, Sealing of cans

Download

If you are unable to download a file

Please try the following solution.

- Please press Ctrl+F5 to clear the cache of your web browser and try again.

- Please restart your web browser and log in again to try again.

- Please change your web browser to another browser and try again.

- Restart the computer and try again.

- Please try again on a different computer.

-

μB1600 Datasheet

Date: 2023-08-04 Rev.08

PDF (3,985 KB)

Login Required

-

μB1600 Datasheet

Date: 2023-08-04 Rev.08

PDF (3,985 KB)

In this website, we provide only the latest version of information including instruction manuals as of our products. Therefore, the newest versions of manuals on the website might be not same as the ones of products you purchased in the past.