"On-site operating" is easy with a manual stage and sophisticated dedicated software

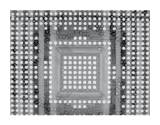

With the stage handle, you can flexibly move the object to the desired position. And with the large front window, you can operate it as if you are touching your hand directly. The product enables easy inspection of the BGA shorts (bridges), chips, and voids by using it on Printed Circuit Board Assembly lines.

Features and Benefits

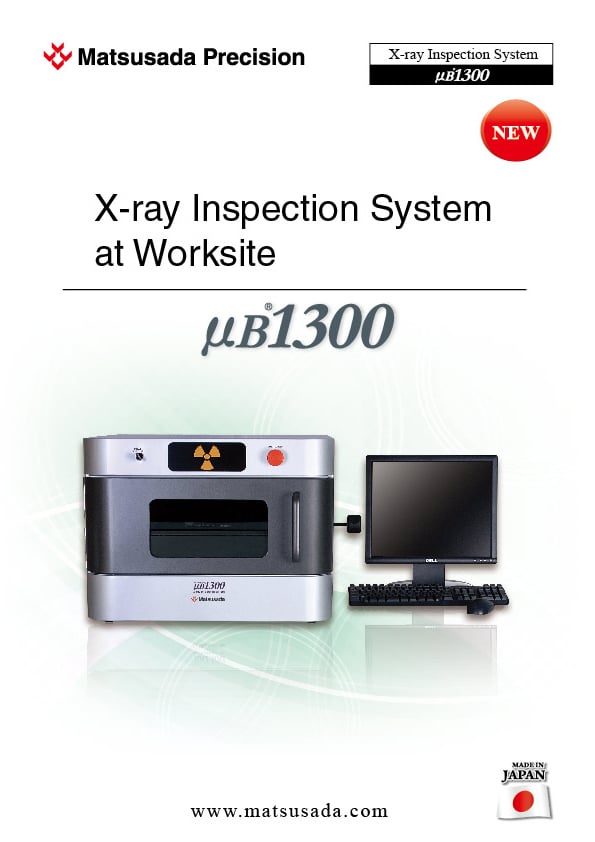

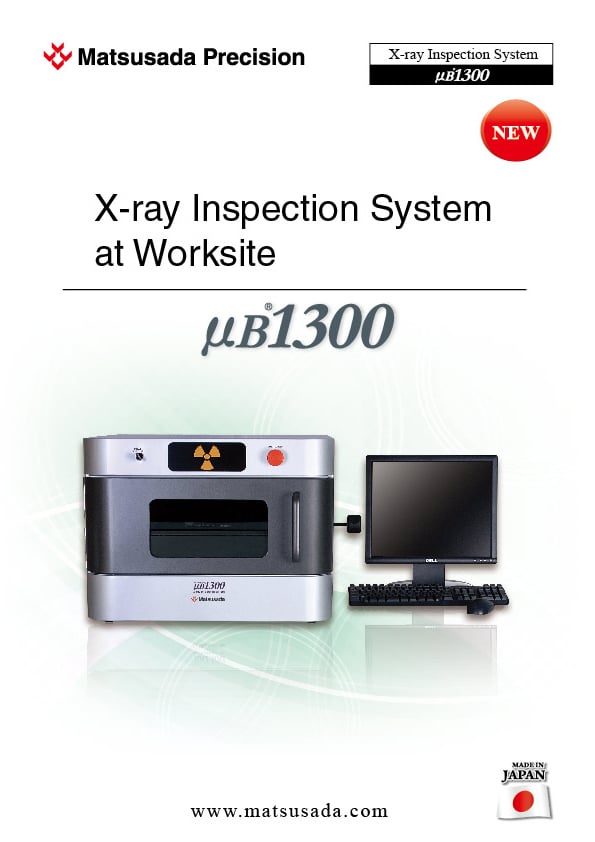

Compact benchtop design

W: 24.5 inches(620 mm) x D: 27.4 inches(695 mm) x H: 18.3 inches(465 mm)

Compact size for on-site use.

Multifunctional rotatable stage

With the rotatable stage, the sample can be rotated 360° for observation.

Two-inch X-ray camera

Equipped with a compact and high-resolution X-ray camera. Imperceptible penetrating X-rays can be viewable.

Safety

Low leakage X-ray dose

In case you forget to turn off the X-ray source, the system automatically stops X-ray radiation after a set time has elapsed. The maximum setting is 60 minutes.

Emergency stop button

This button is to be used only in an emergency. It stops X-ray radiation immediately. The maximum setting is 10 minutes.

Interlock

If the door is opened during the X-ray radiation, the X-ray operation is immediately stopped.

Interlock function

Models

| Model | Tube voltage | Stage Size | Imaging visual field size |

|---|---|---|---|

| μB1300 | 20 to 60 kV | 10.24 x 10.24 inches | 2 inches |

Functions

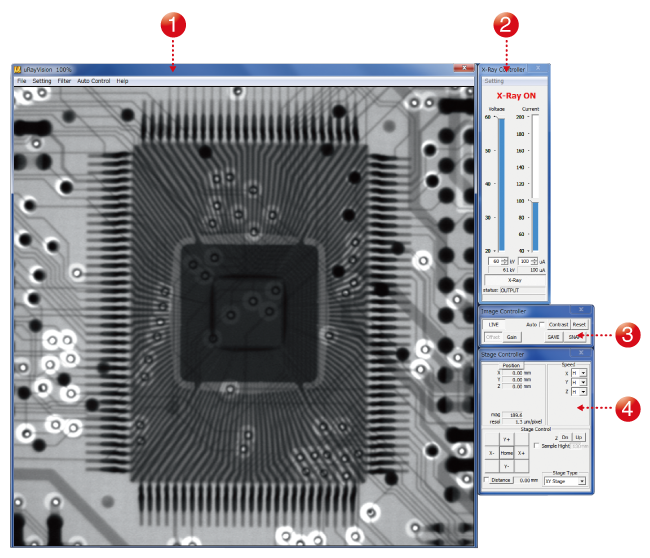

Dedicated software for capturing images, µRayVision

µRayVision, the system’s dedicated software, not only makes controlling the X-ray beam easy, but also provides a variety of image processing and measurement functions.

- (1) High-definition imaging

- Allows high-definition images to be displayed in real-time.

- (2) X-ray controller

- Allows you to turn the X-ray source on and off and to control the tube voltage and current.

- (3) Image controller

- Allows you to configure the image capture settings, including the moving-image filter and display range settings.

- (4) Stage controller

- Allows you to operate the stage using a mouse.

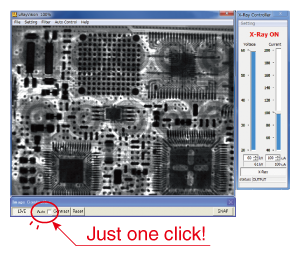

Automatic contrast adjustment function

Invisible images are automatically arranged at its contrast to make it visible.

Image processing software with measurement functions

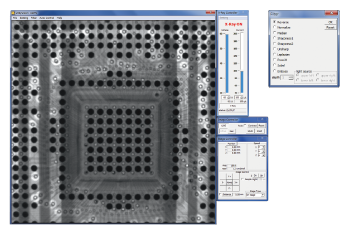

Filters function

µB1300 provides more than ten different types of filters and image processing functions that enable more detailed image analysis. Applying a filter to a moving image enables you to perform real-time image analysis.

Image inversion

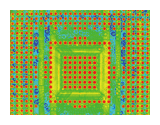

Pseudo color

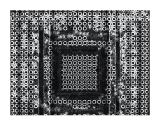

Sobel

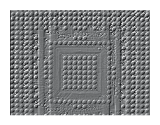

Emboss

Specifications

Options

- -LE

OS/Software language setting (English)

- The language setting of the attached OS/software is English.

- -LF

High resolution imaging system:

| Visual field size | 2.24 inches × 2.52 inches (57 mm × 64 mm) |

|---|---|

| Varid pixels | 150 M pixels |

| Density resolution | 14-bit 16384 tone |

- -LM60

Microfocus X-ray generator

| Tube voltage | 20 kV to 60 kV |

|---|---|

| Tube current | 150 μA |

| Focal spot size | 5 µm |

- -L(***V)

Input voltage option

- Input voltage is changed to 110 V, 115 V, 120 V, 200 V, 220 V, 230 V, 240 V, or Vac ±10% by entering it in ***.

How to order

When ordering, add Option No. in the following order by alphabet, and number to Model No.Example: How to order μB1300-LEFM60(200V)

Sold separately

- STG002: Height Adjustment Stage (Size: 120 mm×120 mm)

- STG056: Height Adjustment Stage (Size: 120 mm×140 mm)

- The adjustable stage can bring the distance between the sample and the X-ray camera closer. So you can take larger field images.

- XDSK200: Aluminum table for option

Special option

- Long-size sample support

- An opening on the unit side enables long samples to be loaded and unloaded. Contact our sales office for details.

Application

Fields and Applications of X-ray Radiography Non-Destructive Testing

- Pharmaceuticals and Cosmetics

- Tablets, Capsules, Catheters, Medical pouches, Foreign objects in the face mask, Cosmetics

- Automobiles and Electric Vehicles

- Automotive components, Wire harness, Batteries, Molded plastic parts, Motor, Insert molded parts, Aluminum die casting, Sensor, Mating parts connection

- Electronics

- Ball grid array (BGA), Integrated circuit (IC) chip, Connectors, Capacitors, LED, Relays, Printed circuit board (PCB), AC adapter, Light bulbs filament, Electrical cable disconnects, Discharge traces of dielectric breakdown

- Advanced Materials

- Carbon-Fiber-Reinforced Polymers (CFRP), Insulation material, Carbon, Dissimilar material joint, Contamination in beryllium

- Precision Conponents

- Probe, Bearing, Mating of plastic parts, Spring position

- Creatures and Plants

- Laboratory rats, Seeds, Flowers, Shell, Bone, Insects, Rice

- Others

- Microscopic foreign matter contamination, Voids in welding, Plastic bottle, Sealing of cans

Download

If you are unable to download a file

Please try the following solution.

- Please press Ctrl+F5 to clear the cache of your web browser and try again.

- Please restart your web browser and log in again to try again.

- Please change your web browser to another browser and try again.

- Restart the computer and try again.

- Please try again on a different computer.

-

μB1300 Datasheet

Date: 2023-08-04 Rev.05

PDF (2,710 KB)

Login Required

-

μB1300 Datasheet

Date: 2023-08-04 Rev.05

PDF (2,710 KB)

In this website, we provide only the latest version of information including instruction manuals as of our products. Therefore, the newest versions of manuals on the website might be not same as the ones of products you purchased in the past.