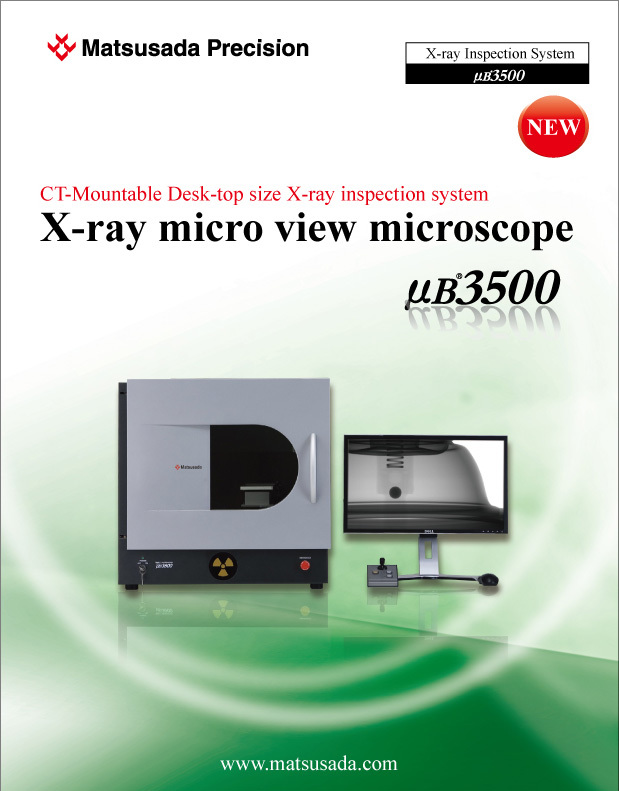

Microfocus X-ray microscope

Benchtop size x-ray micro view microscope with CT scanner

- Max X-ray Voltage: 80kV

- Max X-ray Power: 12W

- A lateral irradiation type

- CT Unit (option)

μB3500 is no longer available as we stopped the production and sales of this model in November 2021. Meanwhile, we support.

Benchtop size X-ray inspection system with CT Scanner function

With the combination of lateral irradiation and a high-resolution digital imaging camera, µB3500 can realize various nondestructive testing and offer a clear image with no distortion to the edge of the image. µB3500, with such a compact Benchtop size, equipped with a rotating stage and joystick for easy operation as well as interlock function, emergency stop function for safer operation, and will satisfy demanding needs for x-ray nondestructive testing.

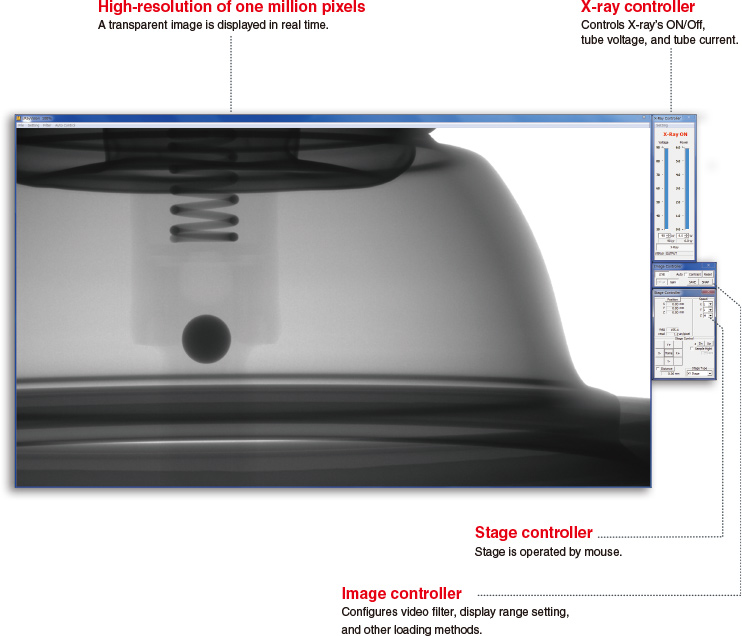

Simple operation allows for use of necessary functions by "anyone" "in no time"

The accompanying dedicated software not only allows for stage control and simple X-ray operation but also features a variety of image processing and measurement functions. It is a simple and easy observation and analysis at the micro/macro level and in various directions. And the reduction of judgment errors and wrong inspection parts is enhanced by the following functions. And more, dedicated software for advanced image processing and analysis is standardly included.

Features and Benefits

Hardware

- Microfocus x-ray tube

- Lateral irradiation

- X axis, Y axis, Z axis, and rotary axis are included to support easy observation.

- Operating the stage with the joystick while looking inside through the big window

- Low-leakage x-ray dose (less than 1 µSv/hr)

- Safety functions: interlock, emergency stop and so on

Software

- 12-bit density resolution

- Density processing: three dimension (3D), pseudo color, pseudo stereo and so on

- Intensity processing: brightness, contrast, non-linear contrast stretch (gamma), filtering, inverting, binary, histogram and so on

- Measuring functions: distance, angle, and area

Possible applications

- A work that cannot be placed on its side

- Composites, ceramics and plastics

- Electronic and electrical components

- Populated and unpopulated PCB's

Model

| Model | X-ray generating part | Shooting part | Stage part | Input voltage | Amount of X-ray leakage | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tube voltage | Tube current | Focal spot size | Visual field size | Effective pixels | Concentration resolution power | Monitor | Sample platform | Loadable sample size | XY stroke | Z stroke | Turning stroke | Moving operation | ||||

| Size | Load capacity | |||||||||||||||

| µB3500 | 20 kV to 80 kV | 150 µA MAX | 5 µm | 4.49 x 1.52-inch (mm) | 2304 x 1300 million pixels | 14 bit | 27 inch | Φ3.93-inch (100 mm) |

2kg | Φ3.93 x Φ8.66-inch (Φ160 x H 220 mm) |

X: 8.46-inch (215 mm) Y: 7087-inch (200 mm) |

1.96 (50) | 360° | Direction given by a mouse operation and joystick can be used at the same time | AC 115 V, 50/60 Hz | 1 µSv/hr or less |

Functions

Lateral irradiation allows for simple fixation of work

Also, X-axis (left and right), Y-axis (front and back), Z-axis (up and down), and rotary axis (turning) are included to support easy observation.

A round work can be easily observed by placing it on the stage and turning it 360 degrees. The stage can be moved to the left/right, front/back, and up/down, allowing for easy operation.

A work that cannot be placed on its side can be easily observed just by placing it on the stage. Changing the stage platform allows for inspection of several works in a row.

As the top panel door opens,a long or heavy work (10 kg)* can easily be loaded on the stage.

* Equipment that supports 10-kg work is optional.

Operability is further enhanced by operating the stage with the joystick while looking inside through the big window.

Easy and secure

Functions that require no experience and functions that are secure and safe

Easy Automatic conditioning function

Extending the life of X-ray tube

Date and time of initial use are recorded. The conditioning process is automatically selected based on how many hours have passed since that day to ensure optimum conditioning.

Note: Proper conditioning and operation can significantly extend the life of x-ray tubes.

Secure Latest ACC function

Just click for a new work

The automatic contrast control (ACC) function allows for the optimization of contrast in images. Anyone can easily obtain fine, transparent images.

SecureSimple shooting with the previous conditions

Calling up the shooting condition file for previous images allows pictures to be taken with the same conditions. Nobody will make mistakes when setting conditions.

Safe Interlock function

The X-ray stops the moment the door opens.

Safe Auto-OFF function

To prevent against forgetting to turn off the X-ray, the X-ray will automatically turn off after a preset time. You can set the time for up to 30 minutes.

Safe Emergency stop function

Just pushing this button during an emergency can stop the X-ray and stage.

Software

µRay®Vision

Simple operation allows for the use of necessary functions by "anyone" "in no time".

The accompanying dedicated software, "µRay®Vision", not only allows for stage control and simple X-ray operation but also features a variety of image processing and measurement functions.

Operability 1Simple observation and analysis

Easy observation and analysis at the micro/macro level and in various directions

With the reduced display function, you can easily make comparative observations.

By switching from the high-resolution display to the reduced display, you can perform observation/analysis of the sample by comparing it with previously saved images.

With a move and a click, details can easily be observed.

This function is helpful when "you want to observe the details of a sample while maintaining high resolution".

Because the stage moves to the part that's clicked, no details will be missed.

By gradually moving the stage, the whole area can be observed without missing anything.

Operability 2Easy lot inspection

Reduction of judgment error and wrong inspection parts is enhanced by the following functions.

With the function for coloring at the designated brightness, defective parts can be discovered easily.

This function is for identifying the concentration value for parts with foreign materials or porosity based on the defective sample. This function can place color on the concentration for the designated range only.

Inspectors can easily make determinations as color is added to the range with the concentration value determined to be defective.

With the area measuring function, conformity/non-conformity can easily be determined based on the area's size.

This function is helpful when performing a void ratio of BGA or when determining the difference in size for a preset shape or in similar items. As the measurement results are given in numeric values, making determinations is easy. The area, number, area of holes, and area ratio can all be measured.

Specifications

Options

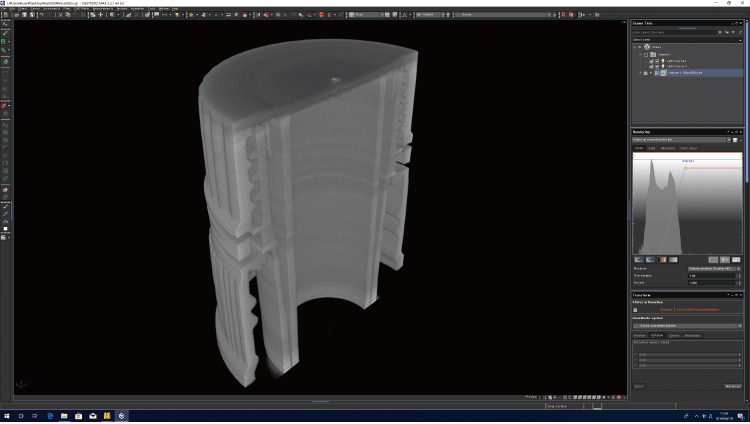

CT unit: 2D/3D analysis software

Although the fluoroscopy equipment can provide only projected images, the CT unit can provide 3D images. By specifying the given surface of the 3D image, the tomographic image of the surface is displayed.

-LW: Stage with a load capacity of 10 kg

Accessory

Aluminum dedicated desk: XDSK300 Sold separately

Separately sold good

Applications

Fields and Applications of X-ray Radiography Non-Destructive Testing

- Pharmaceuticals and Cosmetics

- Tablets, Capsules, Catheters, Medical pouches, Foreign objects in the face mask, Cosmetics

- Automobiles and Electric Vehicles

- Automotive components, Wire harness, Batteries, Molded plastic parts, Motor, Insert molded parts, Aluminum die casting, Sensor, Mating parts connection

- Electronics

- Ball grid array (BGA), Integrated circuit (IC) chip, Connectors, Capacitors, LED, Relays, Printed circuit board (PCB), AC adapter, Light bulbs filament, Electrical cable disconnects, Discharge traces of dielectric breakdown

- Advanced Materials

- Carbon-Fiber-Reinforced Polymers (CFRP), Insulation material, Carbon, Dissimilar material joint, Contamination in beryllium

- Precision Conponents

- Probe, Bearing, Mating of plastic parts, Spring position

- Creatures and Plants

- Laboratory rats, Seeds, Flowers, Shell, Bone, Insects, Rice

- Others

- Microscopic foreign matter contamination, Voids in welding, Plastic bottle, Sealing of cans

Download

If you are unable to download a file

Please try the following solution.

- Please press Ctrl+F5 to clear the cache of your web browser and try again.

- Please restart your web browser and log in again to try again.

- Please change your web browser to another browser and try again.

- Restart the computer and try again.

- Please try again on a different computer.

-

μB3500 Datasheet

Date: 2020-02-10 rev. 04

PDF (4,419 KB)

Login Required

-

μB3500 Datasheet

Date: 2020-02-10 rev. 04

PDF (4,419 KB)

In this website, we provide only the latest version of information including instruction manuals as of our products. Therefore, the newest versions of manuals on the website might be not same as the ones of products you purchased in the past.