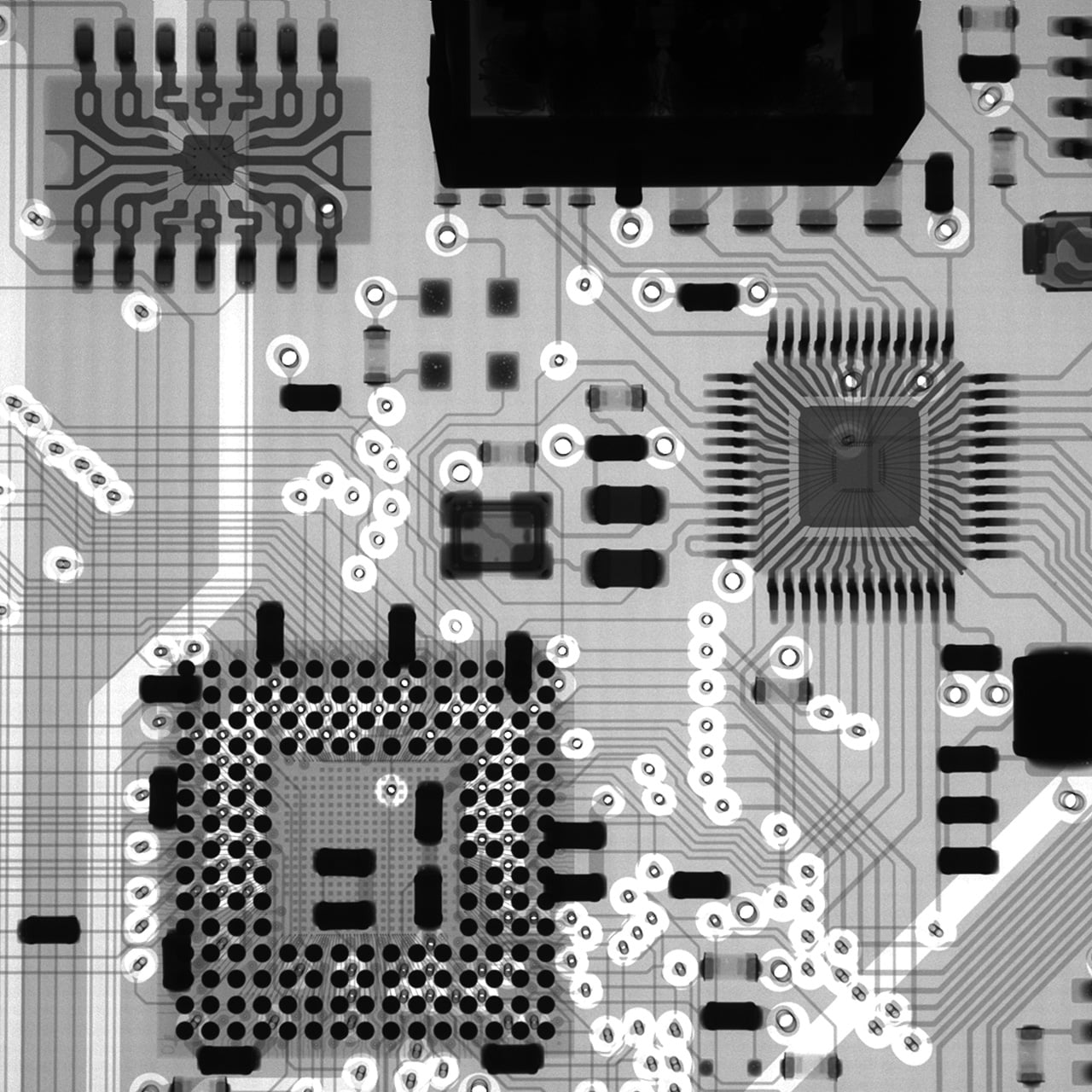

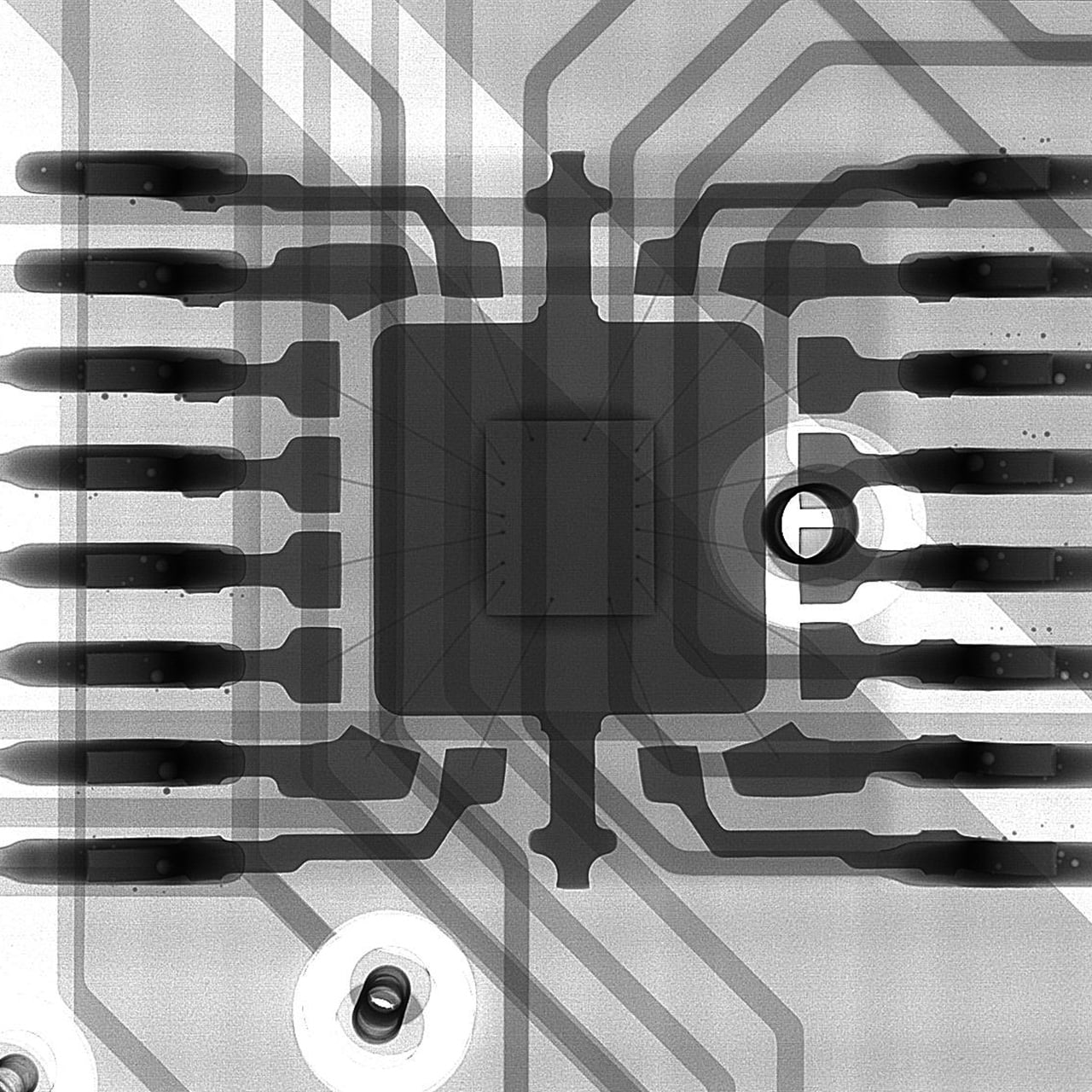

The precision µB3200 is a benchtop, inexpensive 60kV X-ray inspection system ideal for spot-checking SMT lines. We provide comprehensive electronic Printed circuit board defect detection and quality assurance for the SMT industry worldwide.

Suitable for Small Parts

"precision μB 3200" is a benchtop entry-level X-ray inspection system. The compact X-ray inspection system fits directly on the desk to use it anywhere at small factories or offices.

And, you can adjust the geometric magnification of the sample by raising or lowering the detector position

Size of Stage, Shooting Range by the Movement

The "precision μB3200" is ideal for taking images of small circuit boards and small components. For example, the maximum monitor image magnification is 125 times, the inspection area is 2.5 mm × 2.8 mm, and the applicable shooting range is 150 mm × 200 mm.

Easy Replacement

X-ray Tube Unit Replacement Steps

To replace the X-ray tube unit, remove the panels on the top and at the back side, and pull out the X-ray tube unit from the bottom part.

X-ray Detector Replacement

Slide off the detector attached to the top inside of the unit to replace it with a new one.

For the Safety

The X-ray leakage measurement we offer is conducted from all directions of each unit to confirm that it is less than 1μSv/hr before delivery.

It is the extremely low level that has no impact on the usage in daily lives.

-

Safety door switch

X-rays cannot be irradiated when the door is open. If the door opens during X-ray irradiation, the Safety Door Switch function makes the X-ray emission stop.

-

Product status display LED

It indicates the product status on the front panel if the X-ray irradiation is on, the door is open, and other status.

-

Auto-off

If the X-ray source is mistakenly on even after the shooting is completed in the image analyzing process where you need to concentrate, using the auto-off function, you can set the time beforehand to turn off the X-ray source automatically.

-

Emergency stop button

When you press the emergency stop button, the X-ray is stopped immediately.

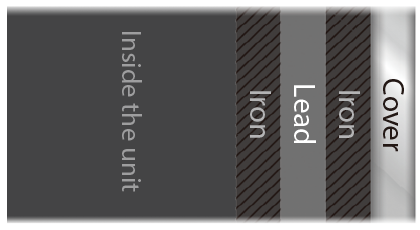

X-Ray Shielding Technology

To ensure safe and reliable installation, we have carefully designed radiation shielding. In general, lead used for shielding is a soft and easily deformed material, but by adopting a multi-layered structure combined with steel plates, it can be used for a long time without the deformation of lead.

Datasheets

If you are unable to download a file

Please try the following solution.

- Please press Ctrl+F5 to clear the cache of your web browser and try again.

- Please restart your web browser and log in again to try again.

- Please change your web browser to another browser and try again.

- Restart the computer and try again.

- Please try again on a different computer.

Information on related articles in Technical Knowledge

Similar products

-

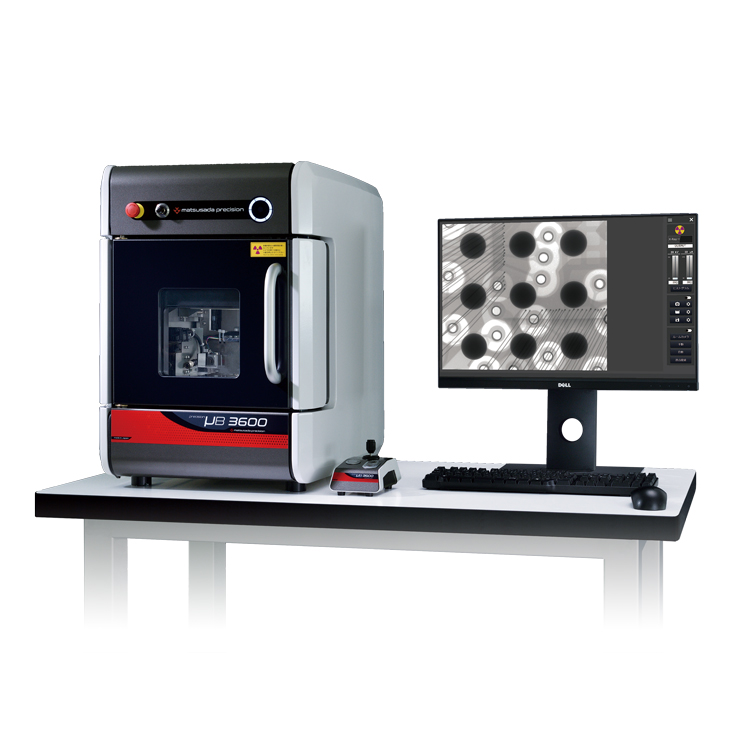

precision µB3600

- X-ray tube voltage

- 90kV

- X-ray power

- 13.5W

X-ray Inspection systemBenchtop High-spec Model

-

New

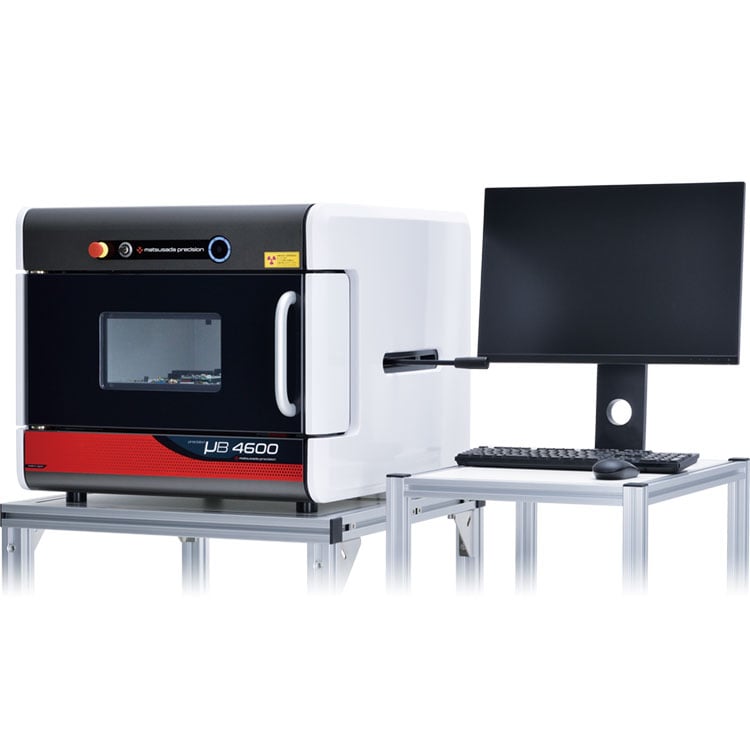

precision µB4600

- X-ray tube voltage

- 60 to 90kV

- X-ray power

- 9 to 60W

X-ray Inspection systemHigh Power Model

-

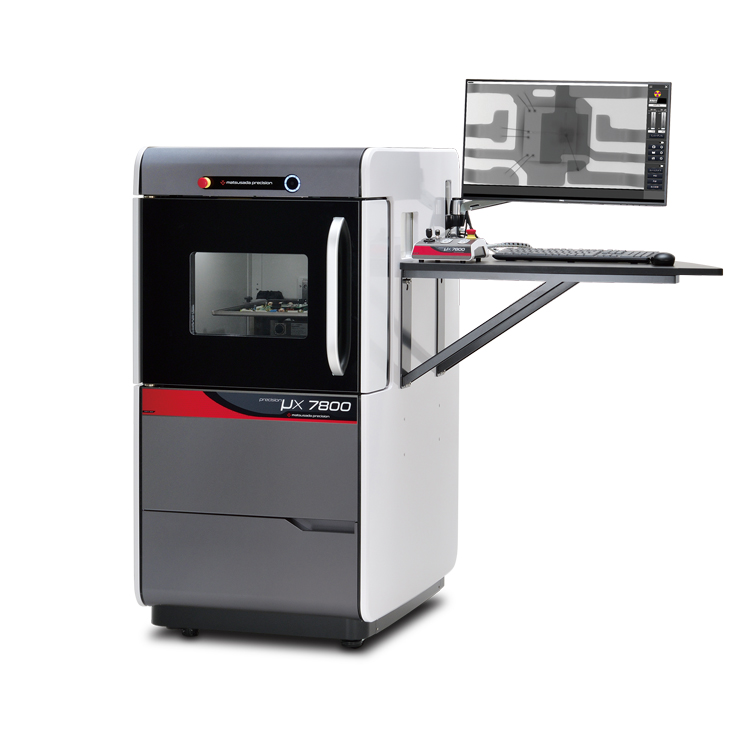

precision μX7800

- X-ray tube voltage

- 90kV

- X-ray power

- 18W

X-ray Inspection SystemAll-round Model