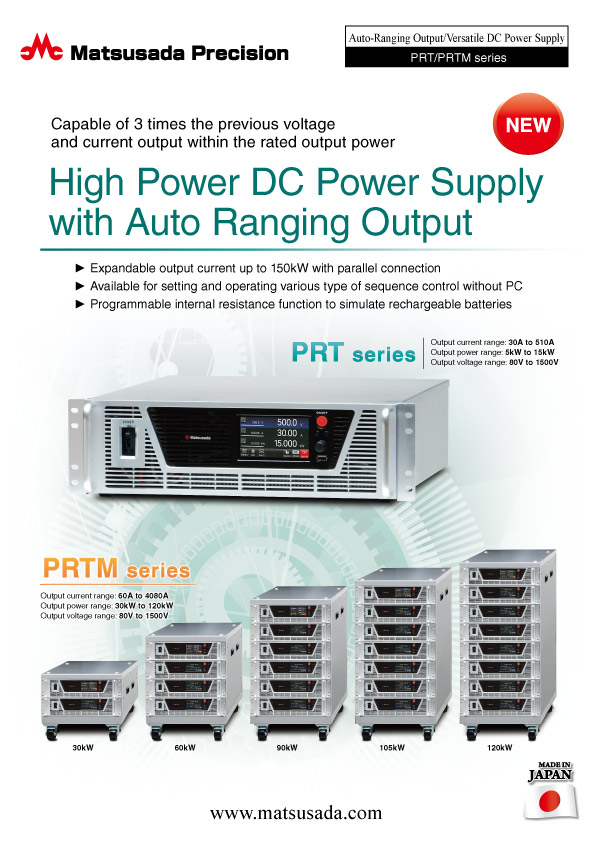

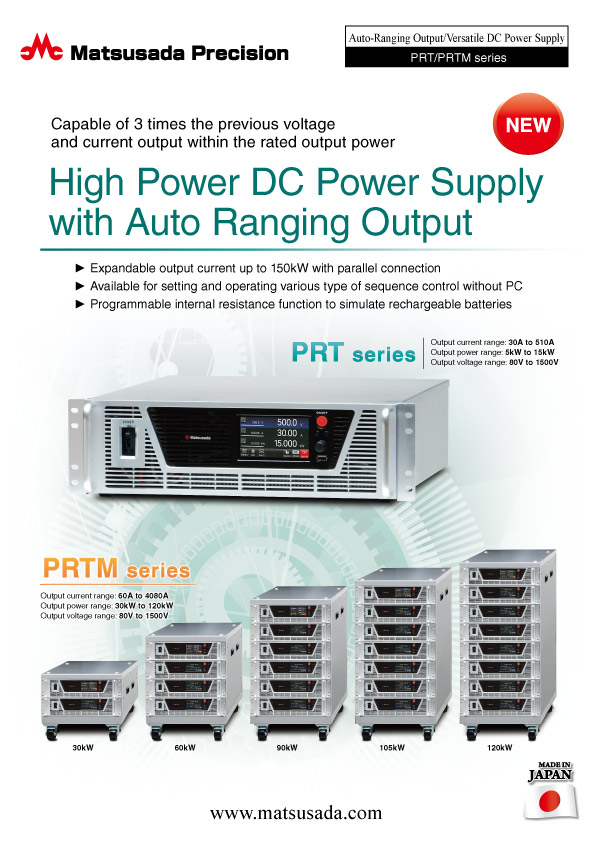

HIGH POWER DC POWER SUPPLY WITH AUTORANGING OUTPUT

- Max Voltage: 80V to 1500V

- Max Current: 60A to 4080A

- Max Power: 30kW to 120kW

- Space saving

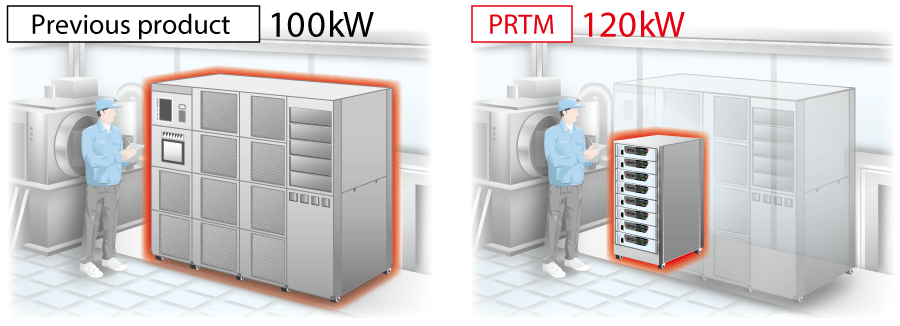

High power up to 120kw in a slim rack

PRTM series, a high power DC power supply integrated the PRT series models in a single rack cabinet, offering at least three times the output range more than the previous ones.

This DC power supply employs a total current display and also provides elaborated protection as standard equipment. Accordingly, it provides strong support, especially for customers' research and development requiring high current and high power.

Refer to the PRT series for base model details. PRT series

Note: The PRT series disassembled from the PRTM series can be used as a stand-alone PRT unit. However, wiring and settings must be done by the customer, and they are out of warranty.

FEATURES

-

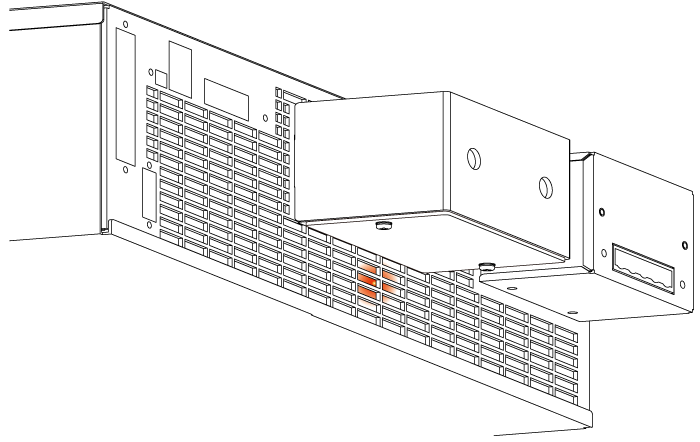

1. MORE SPACE SAVING FOR BETTER WORKPLACE

Introducing the extremely compact PRTM makes more effective use of your workspace. We have developed the smaller regeneration DC power supply for space saving aimed at installing other measuring tools, which makes effective use of the space at the workplace.

-

2. HOW TO COMPACT

State-of-the-art semiconductor

In order to minimize the heat generation inside the power supply, we adopted the latest device, including semiconductor elements of high efficiency, via thorough examination. This enables the product to provide a sufficient cooling function to maximize high performance.Air-through circuit block technology

With the improvement of the air-through circuit block, the product has been made smaller, and we have also put more focus on the improvement of block arrangement, contributing to excellent space efficiency by extremely reducing dead space. Consequently, we achieved the significant development of high-density mounting technology. While extra space inside the device had been required to release the heat so far, we successfully made the product even smaller to ensure a total height of a mere 133 mm. -

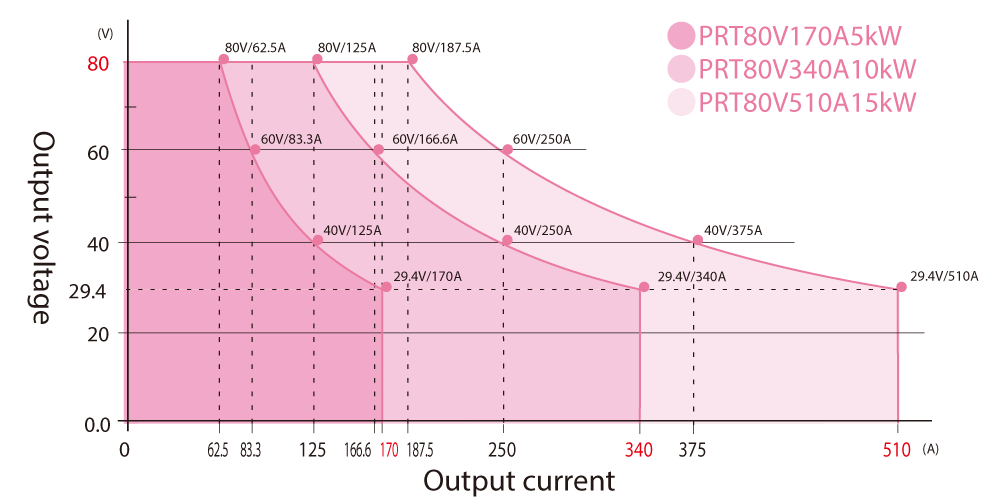

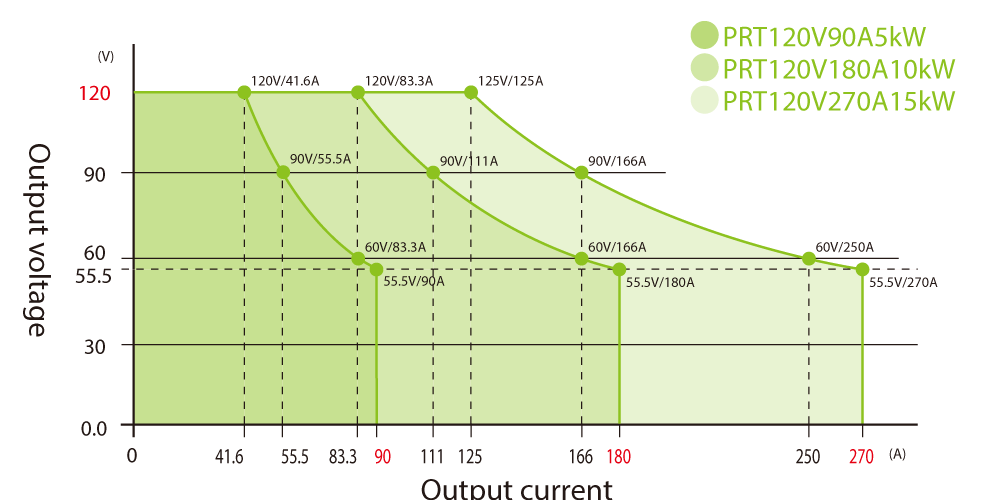

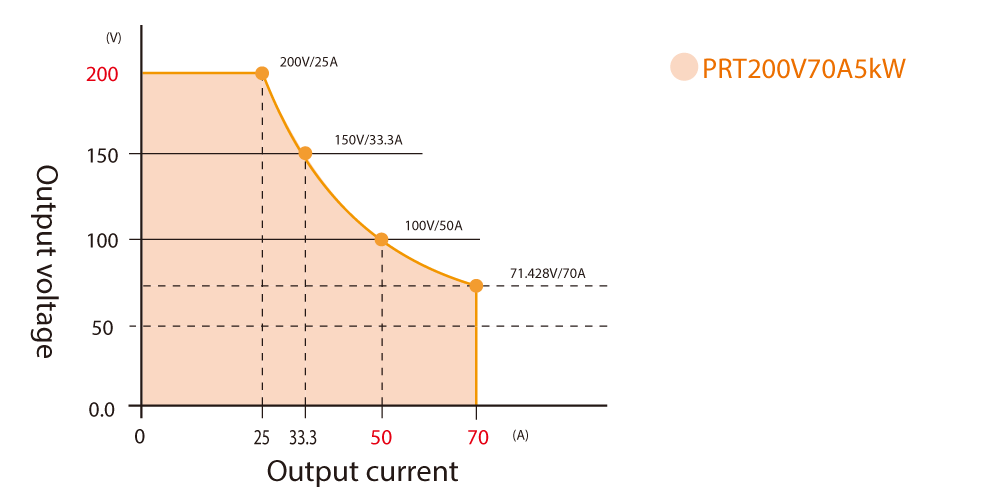

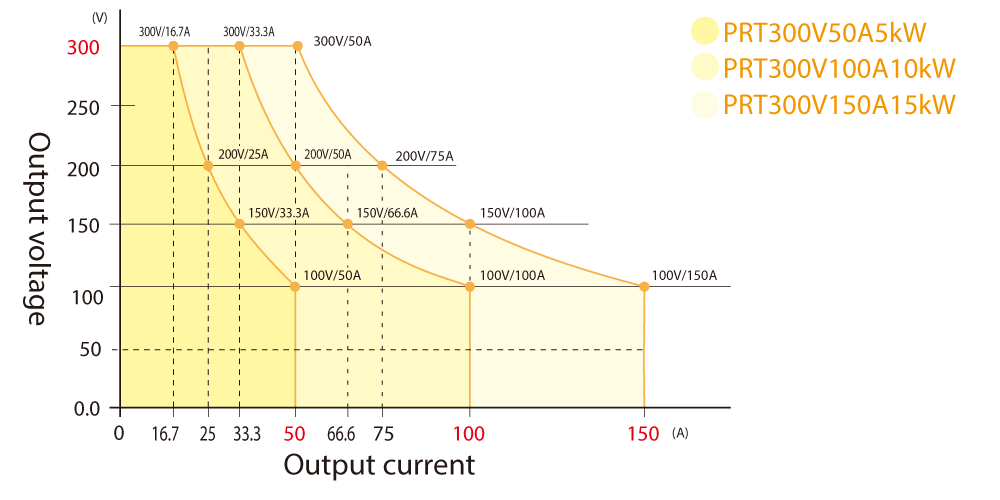

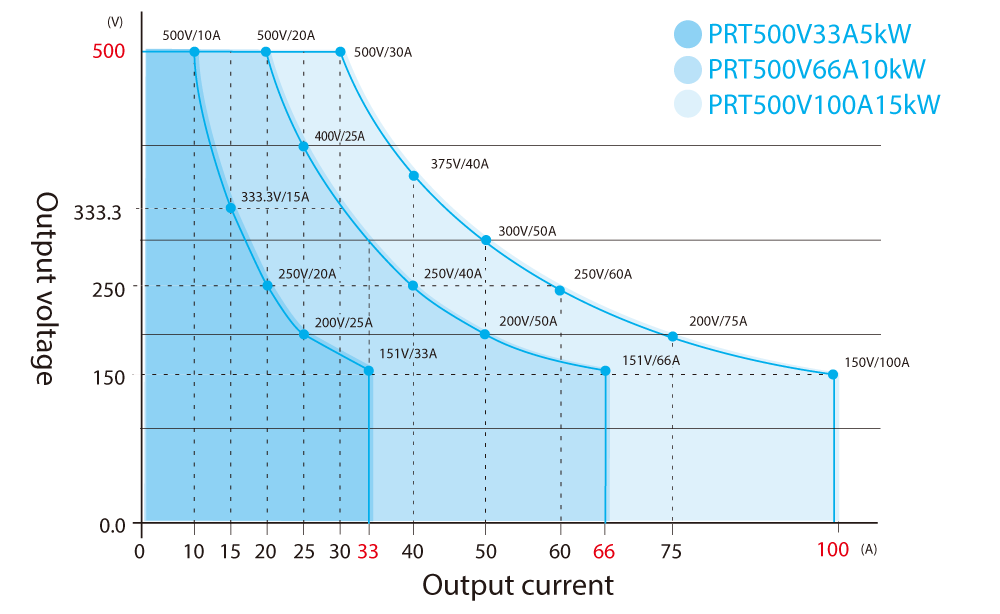

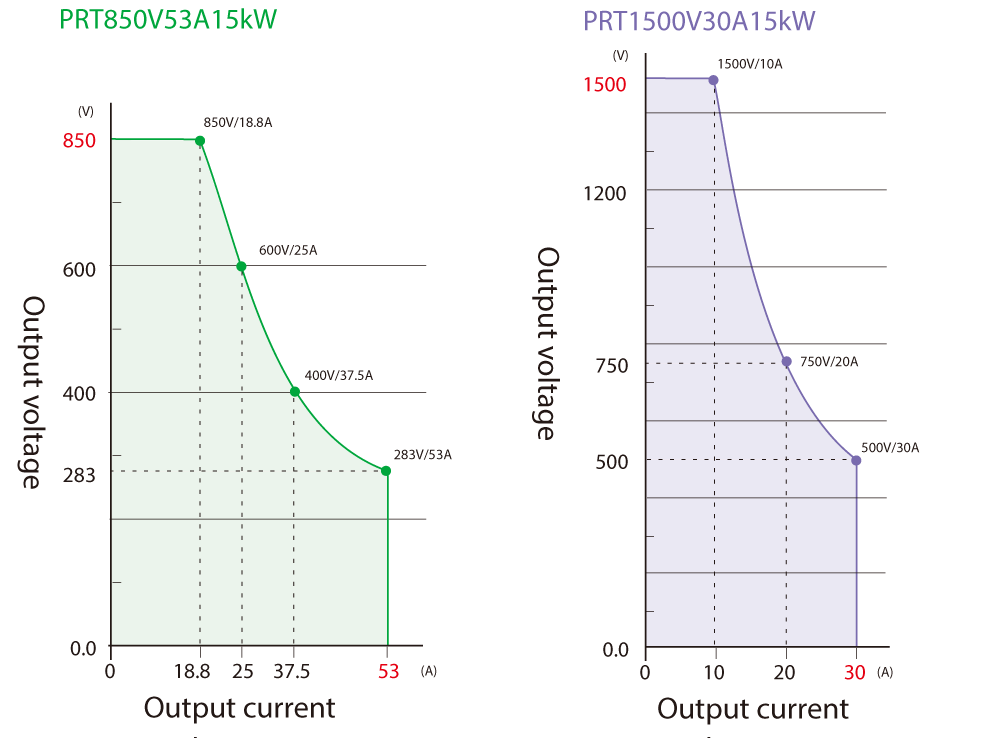

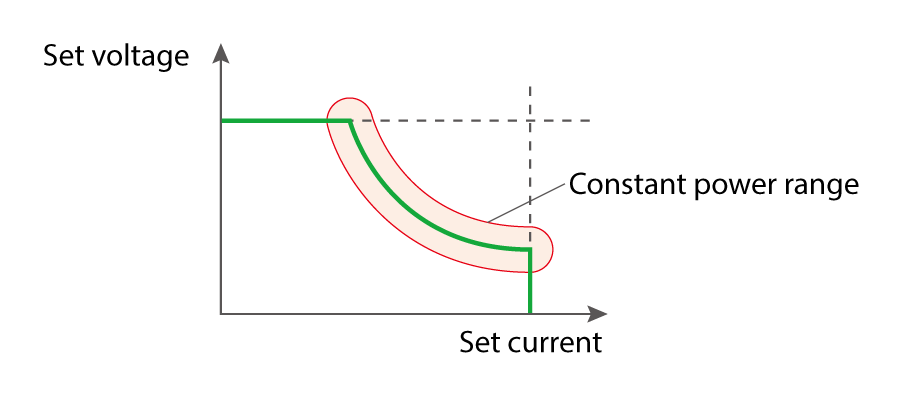

3. OUTPUT RANGE GRAPHS

With the turbo function, an autoranging of voltage and current output compared to conventional DC power supplies.

- Equipped with a turbo function to achieve an autoranging of output.

- Expandable output current up to 150kW with parallel connection

- CV/CC priority setting function enables suppression of overshoot by setting the voltage/current increase sequence with the output ON

- Variable internal resistance function enables simple simulation of rechargeable batteries

- The sink current suppression reduces the reverse current flowing from the load to the unit to prevent a voltage drop on the load as the output is OFF or the set voltage is lowered.

- Low-noise switching method ideal for research & development

APPLICATIONS

-

Electric Vehicles (EVs), and Drones

Test and Evaluation of electronic components such as inverters, DC/DC converters, on-board chargers (OBC), DC motors, compressors, power relays, heaters, pumps, fuses, harnesses used in Battery Electric Vehicles (BEVs), Plug-in Hybrid Electric Vehicles (PHEVs), Hybrid Electric Vehicles (HEVs), and drones

-

Batteries

Charge and discharge cycle tests of high-voltage, high-power battery packs for lithium-ion batteries (LIB) such as Lithium iron phosphate (LFP) battery packs

-

Hydrogen and Ammonia production, Fuel cells

Development of hydrogen and ammonia production equipment (electrolysis, electrolytic synthesis, catalyst, and electrochemistry tests) and fuel cell technologies such as solid oxide fuel cell (SOFC) and solid oxide electrolysis cell (SOEC).

-

Power devices

Semiconductor Processing and burn-in of power semiconductors such as SiC, GaN, IGBT, MOSFETs, and laser diodes

-

Photovoltaic cells

Testing and evaluation of solar inverters (PV inverters), Hybrid inverters, junction boxes

-

Scientific Research, etc

In addition, the PRT/PRTM series is designed to meet a variety of DC power supply applications.

Models

We offer more models other than the models with the output bands below, so feel free to contact our sales representatives for details.

| Model | Maximum output | Power supplies installed [units] | ||

|---|---|---|---|---|

| Voltage [V] | Current [A] | Power [kW] * | ||

| PRTM80V1020A30kW | 80 V | 1020 A | 30 kW | 2 units |

| PRTM80V1530A45kW | 1530 A | 45 kW | 3 units | |

| PRTM80V2040A60kW | 2040 A | 60 kW | 4 units | |

| PRTM80V2550A75kW | 2550 A | 75 kW | 5 units | |

| PRTM80V3060A90kW | 3060 A | 90 kW | 6 units | |

| PRTM80V3570A105kW | 3570 A | 105 kW | 7 units | |

| PRTM80V4080A120kW | 4080 A | 120 kW | 8 units | |

| PRTM300V300A30kW | 300 V | 300 A | 30 kW | 2 units |

| PRTM300V450A45kW | 450 A | 45 kW | 3 units | |

| PRTM300V600A60kW | 600 A | 60 kW | 4 units | |

| PRTM300V750A75kW | 750 A | 75 kW | 5 units | |

| PRTM300V900A90kW | 900 A | 90 kW | 6 units | |

| PRTM300V1050A105kW | 1050 A | 105 kW | 7 units | |

| PRTM300V1200A120kW | 1200 A | 120 kW | 8 units | |

| PRTM500V200A30kW | 500 V | 200 A | 30 kW | 2 units |

| PRTM500V300A45kW | 300 A | 45 kW | 3 units | |

| PRTM500V400A60kW | 400 A | 60 kW | 4 units | |

| PRTM500V500A75kW | 500 A | 75 kW | 5 units | |

| PRTM500V600A90kW | 600 A | 90 kW | 6 units | |

| PRTM500V700A105kW | 700 A | 105 kW | 7 units | |

| PRTM500V800A120kW | 800 A | 120 kW | 8 units | |

| PRTM850V106A30kW | 850 V | 106 A | 30 kW | 2 units |

| PRTM850V159A45kW | 159 A | 45 kW | 3 units | |

| PRTM850V212A60kW | 212 A | 60 kW | 4 units | |

| PRTM850V265A75kW | 265 A | 75 kW | 5 units | |

| PRTM850V318A90kW | 318 A | 90 kW | 6 units | |

| PRTM850V371A105kW | 371 A | 105 kW | 7 units | |

| PRTM850V424A120kW | 424 A | 120 kW | 8 units | |

| PRTM1500V60A30kW | 1500 V | 60 A | 30 kW | 2 units |

| PRTM1500V90A45kW | 90 A | 45 kW | 3 units | |

| PRTM1500V120A60kW | 120 A | 60 kW | 4 units | |

| PRTM1500V150A75kW | 150 A | 75 kW | 5 units | |

| PRTM1500V180A90kW | 180 A | 90 kW | 6 units | |

| PRTM1500V210A105kW | 210 A | 105 kW | 7 units | |

| PRTM1500V240A120kW | 240 A | 120 kW | 8 units | |

- The operation confirmation has been conducted in each power supply unit alone beforehand. Once the power supply units are installed, no operation of the rated output is checked.

Functions

Application Operations with Front USB Port

No data logger or no always connected computer required

Shortening time of wiring and preparation, Suited for cycle tests in areas where computers are prohibited.

- Features:Built-in data logging

- Data logging captures the output data at the fastest interval of 0.1 seconds by inserting the USB memory stick. Also, with the dedicated software MLV, the log data is available in CSV format to output.

- Use in places where you cannot always connect a computer

- With the dedicated software MSS, you can save the sequence program data to the USB memory and load it from the front USB port. Thus, the program operation is available by the power supply only.

Functions with Front USB Port and Standard Attached Software

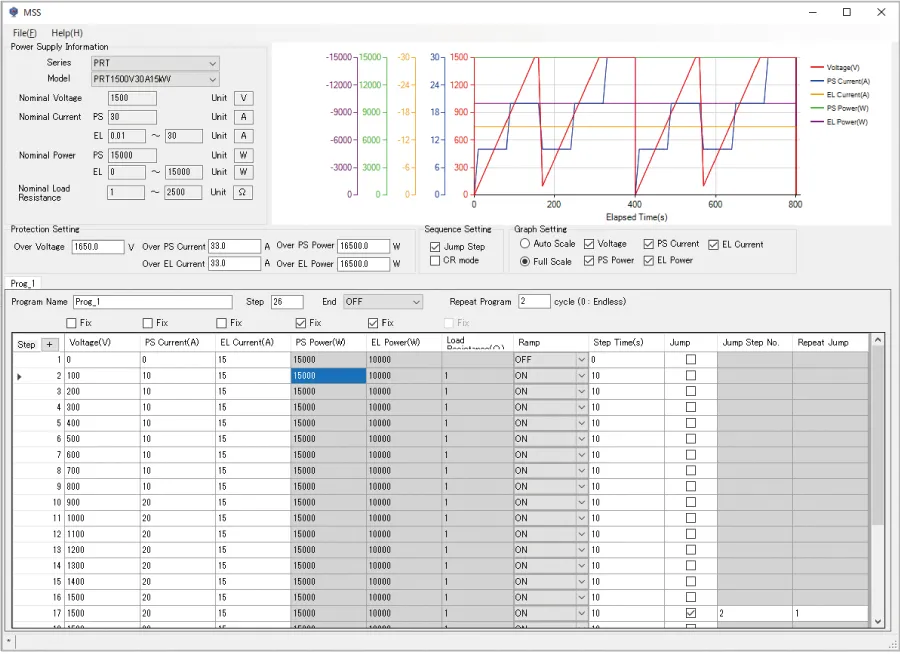

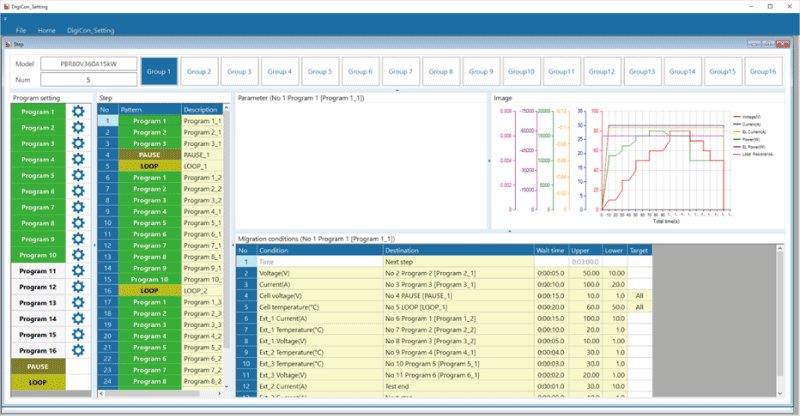

(1) Sequence program function: MSS (Matsusada Sequence Software)

- Easy to use for beginners

- MSS allows you to create sequence program data using the main unit or a computer with the dedicated software (MSS).

The software makes it easier and more convenient to create sequence program data. The created sequence program data can be saved to USB memory, and up to 1,024 steps of the sequence program can be loaded.

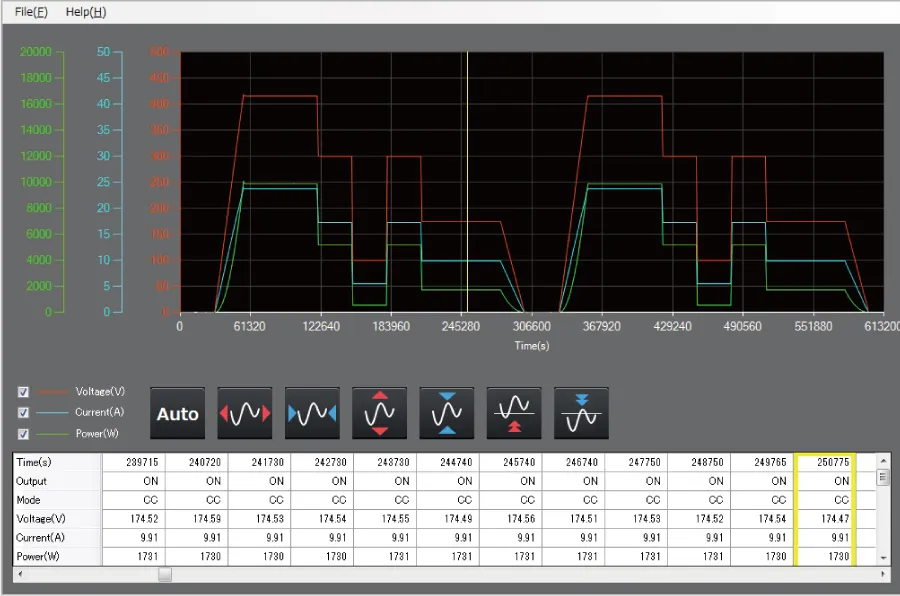

(2) Operation log display: MLV (Matsusada Log Viewer) Operation log

- Instant graphing of operation logs

- Operation log display function: MLV, the dedicated software can read and graph the operation log.

Logging to USB memory is available not only during the sequence operation as described in (1) above but also during the local/external control.

- Easy editing of operation logs

- MLV can select items you need and save them in CSV format, so you can also edit the data in spreadsheet software with no problem.

[Display items]

- Elapsed time

- CC/CV mode

- Output value (Voltage, Current, and Power)

- Status

- Other information on errors, etc.

Large Color Touch Panel

PRT/PRTM series comes with a large color touch panel, realizing its operability and visibility improvement.

- Easy setting of output voltage, current, power, and other parameters !

- Simple setting to complex sequence program !

- New feature with more selectable error detections !

- Equally available in a conventional configuration with the setting dial

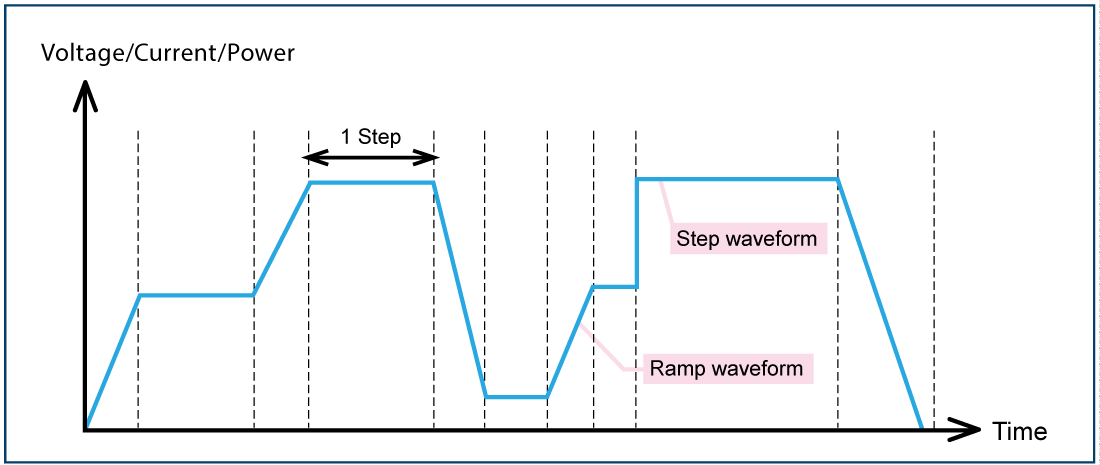

Sequence Programming Function

The sequence programming function allows the programming of parameters such as step time, step amplitude, ramp, CV/CC mode, sequence program end-setting, step jump, and jump count by simply operating on the front panel. This option enables you to generate customized original waveforms, and you can use a great variety of applications including testing evaluation, and verification.

- Step setting time 0.0 to 3,600 s

- For one program, a maximum of 1,024 steps can be configured and saved.

- CV/CC mode can be set for each program.

- Repetition frequency: infinity, or 1 to 999 Program as Image

Program as image

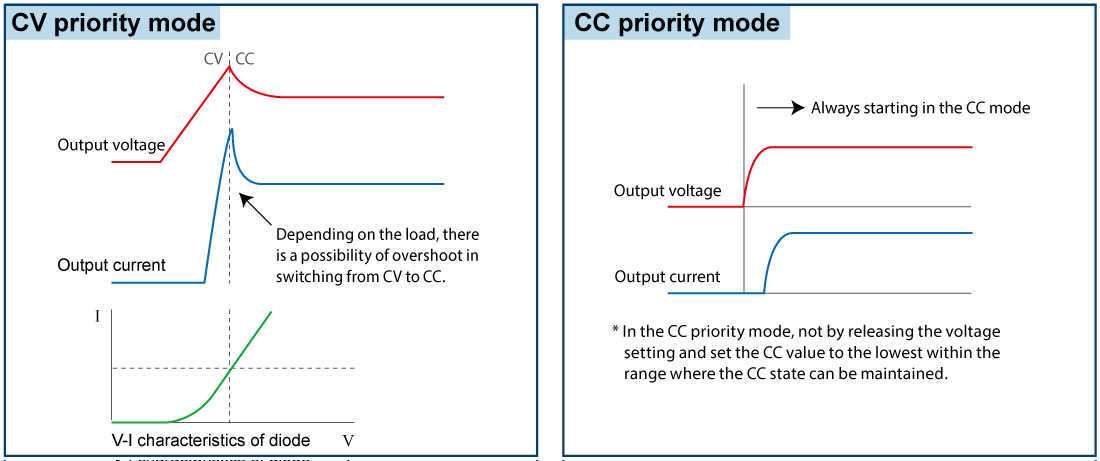

CV/CC Priority Setting Function

CV (constant voltage) priority/CC (constant current) priority mode can be selected and set. As is the case with diodes, a load tends to suddenly change the resistance at certain points. When the device is started in CV mode, the current will be momentarily overshot. In the PRTM series, select the CC priority mode to suppress the occurrence of overshoot. The function can reduce the risk of damaging expensive loads such as high-power laser diodes.

* In the CC priority mode, do not release the voltage setting and set the CC value to the lowest within the range where the CC state can be maintained.

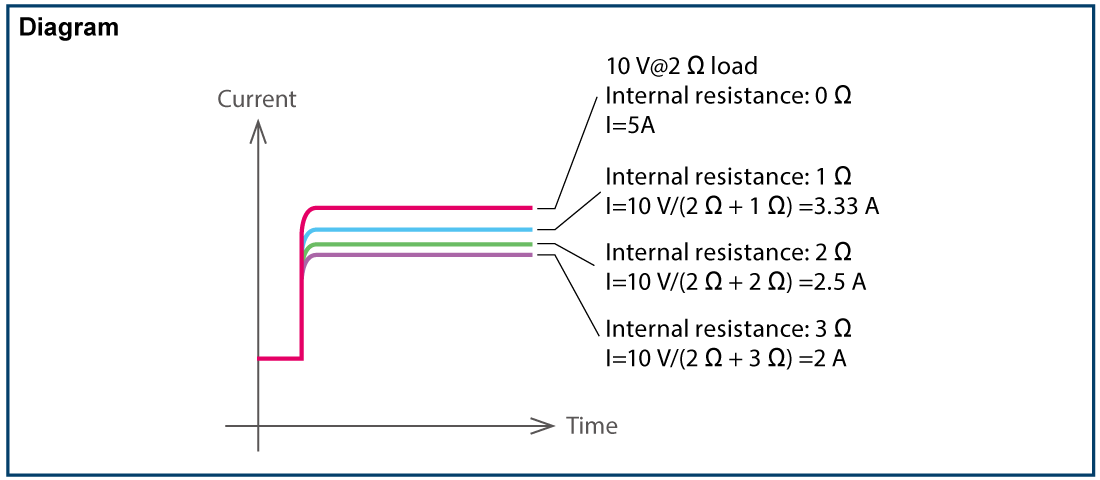

Variable Internal Resistance Function (in CV Mode)

Set the internal resistance to any value to generate a voltage drop when the load current flows.

Batteries, photovoltaic cells, and fuel cells can be simulated.

(The setting range of the internal resistance value is from 0 Ω to the rated voltage/rated current.)

Preset Memory Function

With the preset memory function, the preset values are automatically saved when the power turns off.

Furthermore, up to three different voltage, current, and power settings are also memorized respectively.

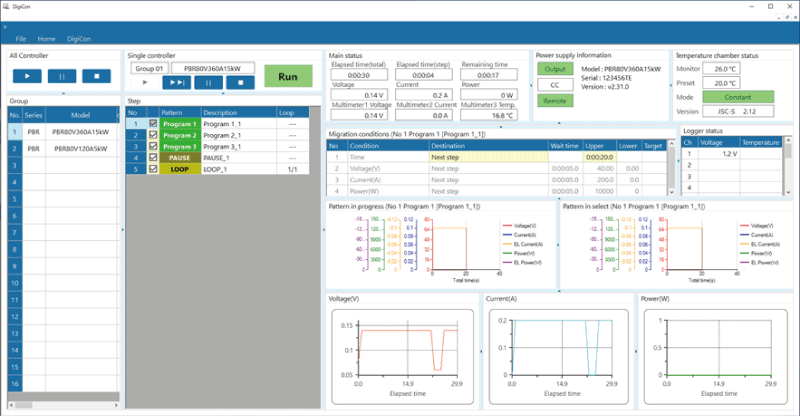

Remote Control Software (Additional Products): DigiCon series

DigiCon is an application package that remotely controls Matsusada Precision's DC power supplies connected via LAN.

The software can control multiple power supplies simultaneously or individually.

- Power control for PRKT, PRT/PRTM, PBR/PBRM, P4KF, PKTS, HARS series

- Full remote control available

- Consists of "configuration software" and "operation software

- Linkage to digital multimeters, data loggers, and thermostatic chambers is possible.

- Easy operation with Graphical User Interface (GUI)

- Automatic Test Equipment (ATE) can be built without programming knowledge.

- Real-time logging, graphing, and data storage

Link with digital multimeters, data loggers, and thermostatic chambers is possible.

Program transitions can be made in response to external conditions by linking with measuring instruments such as digital multimeters and data loggers, as well as thermostatic chambers.

This advanced function allows the program to transition to the next step when the end condition of the instrument is met without waiting for a set time, or to safely terminate the program if a problem occurs during operation.

Easy operation enables speedy construction of Automatic Test Equipment (ATE)

Graphical user interface, including graphical display of set values, allows easy operation.

Automatic Test Equipment (ATE) and inspection systems can be built without programming knowledge.

It can be used in many fields and applications, such as long-term reliability testing of electronic equipment and devices in the automotive, home appliance, and medical fields.

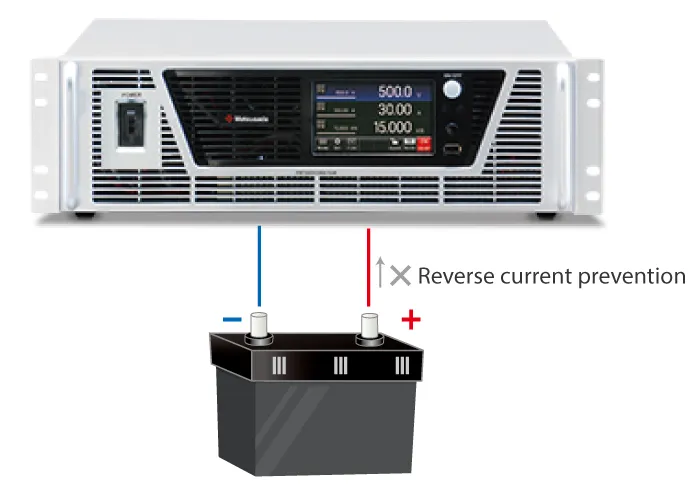

Sink current prevention function

The function is suitable for supplying power to loads with capacities like batteries and capacitors. It reduces the reverse current flowing from the load to the unit in order to prevent a voltage drop on the load as the output is OFF or the set voltage is lowered.

Note: Reverse current cannot be controlled and stabilized. In order to protect the power supply unit, connect a dummy resistor or reverse current prevention diode if the load of the reverse voltage is equal to or higher than the rated voltage (inductive loads, regenerative motors, etc.).

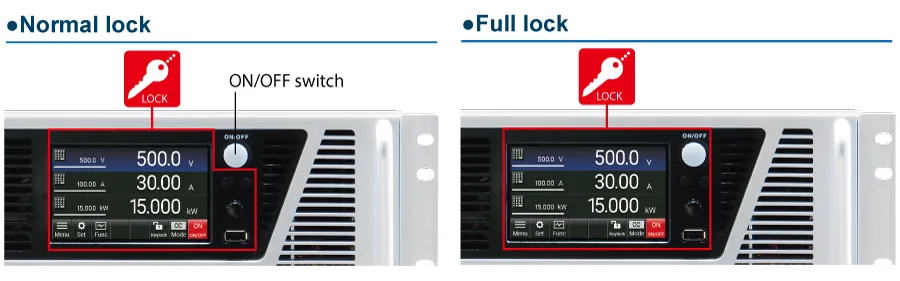

Two-mode Lock Function

The locking is selectable from two setting modes: One is "Full LOCK" to lock all front panel operations, and the other is "Normal LOCK" to lock all operations except the ON/OFF switch.

The function is so user-friendly that the "Full LOCK" mode is provided to ensure the prevention of erroneous operation, and the "Normal LOCK" function facilitates the emergency stop while preventing erroneous operation. Emergency stop operation using the POWER ON/OFF switch is possible in either mode.

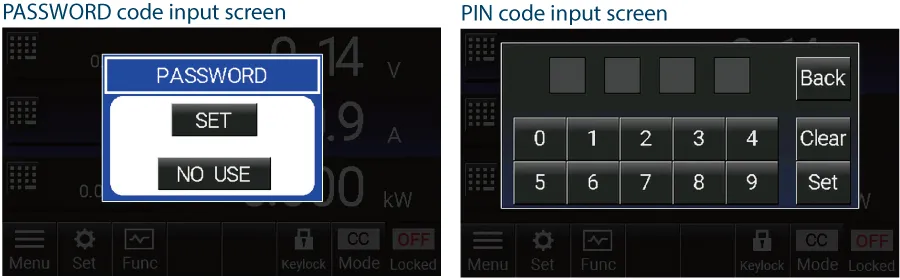

Password Function New

In this function, to cancel the two-mode lock function, input a 4-digit PIN code. (Enable/Disable is selectable.)

Secure Analog Remote Control

The external analog remote control of voltage/current/power is isolated from the output of the power supply as standard.

When controlling/monitoring multiple power supplies, you can use the product more securely as the external analog remote control has a chassis (ground) potential.

External Analog Control

- External output ON/OFF

- Remote sensing

- Remote/Local mode setting

- Status output

- Output monitor

- Output control

(Voltage, Current, Power, Overvoltage protection, Overcurrent protection, Overpower protection)

Residual Voltage Detection LED

- Use for checking residual voltage

- The LED on the rear panel blinks when there is voltage remaining on the DC output terminal in output or at output off. it is useful for reference to check if the voltage remains. Be sure to check the voltage before the operation of the unit.

Constant Power Control Function (CP Mode)

In addition to Constant Voltage control (CV mode) and Constant Current control (CC mode), Constant Power Control (CP mode) is provided.

With CP mode, a constant power supply is provided depending on loads, such as resistors (heaters) whose resistance changes with temperature. It is available without monitoring voltage/current or attaching external control devices (temperature regulators).

Specifications

Options

- -LBr

-

Protective breaker

One overcurrent protection device with a circuit breaker is installed in each rack.

This option is only available for models with six or fewer installed power supplies.

- -LCa *1 *2

-

CAN interface port

Using CAN communications, output controlling and operation status monitoring of these devices can be performed.

- -LEb

-

Eye bolts

Four eyebolts mounted to the top side allow you to move the product using cranes.

- -LGob *1 *2

-

Optical interface port

- -LGob: Optical interface + optical cable 2 meters

- -LGob(Fc5): Optical interface + optical cable 5 meters

- -LGob(Fc10): Optical interface + optical cable 10 meters

- -LGob(Fc20): Optical interface + optical cable 20 meters

- -LGob(Fc40): Optical interface + optical cable 40 meters

The optical communication adapter at the control side should be purchased separately.- for LAN: CO-E32

- for USB: USB-OPT

- for RS-232C: CO-OPT2-25, CO-OPT2-9

- for RS-485: CO-OPT4-25

- for GPIB: CO-G32 (Discontinued in December 2028)

The unit is remotely controlled by isolating with optical communication. As complete isolation is provided by means of optical fiber, this enables advanced prevention of erroneous operation involved with transient phenomenon caused by surges, inductive lightning, external noise, etc.

- -LRs *1 *2

-

RS-232C/RS-485 interface port

Using RS-232C/RS-485 communications, output controlling and operation status monitoring of the devices can be provided.

- -L(400V)

-

Rated input for three-phase 380 Vac to 440 Vac

The rated voltage of the power grid is 380 to 440 Vac, three-phase, 50/60 Hz.

- Other Options

-

Customized Specifications of Rack, Safety Cover, etc.

Customized specifications as of Rack, Safety cover for mistaken input prevention, Blank panel, Emergency stop button, and other options are available on request. Please feel free to contact us.

- Installed only on the Master unit. The Slave unit can be used alone, but no option is supplied.

If you need an option for the Slave unit, please contact us. - Selecting each individual option simultaneously in -LCa, -LGob, and -LRs is not allowed.

How to Order

When ordering, add Option No. to Model No. in alphabetical order followed by the input voltage.

Example: PRTM850V424A120kW-LBrEbGob(400V)

ADDITIONAL PRODUCTS

- Anchors: Material Stainless steel plates(in pairs)

-

Model number: RAC-AMF

[Unit: inch (mm)]

Numbers can be used 2 pcs (pair)

- Remote Control Software

-

Model Name: DigiCon-PRTM

DigiCon is an application package that remotely controls Matsusada Precision's DC power supplies connected via LAN.

The software can control multiple power supplies simultaneously or individually.

For details, Refer to "Remote Control Software".

Dimensions

Download

If you are unable to download a file

Please try the following solution.

- Please press Ctrl+F5 to clear the cache of your web browser and try again.

- Please restart your web browser and log in again to try again.

- Please change your web browser to another browser and try again.

- Restart the computer and try again.

- Please try again on a different computer.

-

PRTM series Datasheet

Date: 2024-10-10 rev.20

PDF (5,282 KB)

-

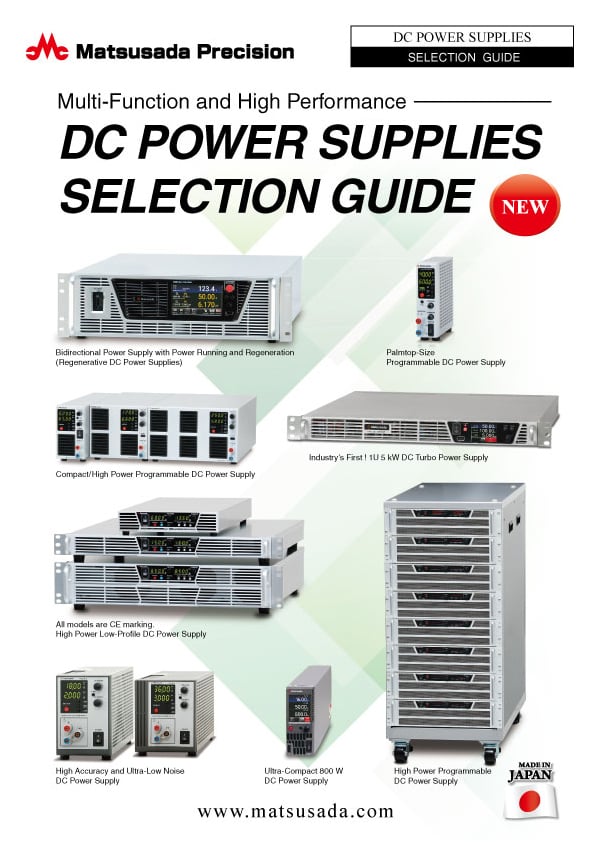

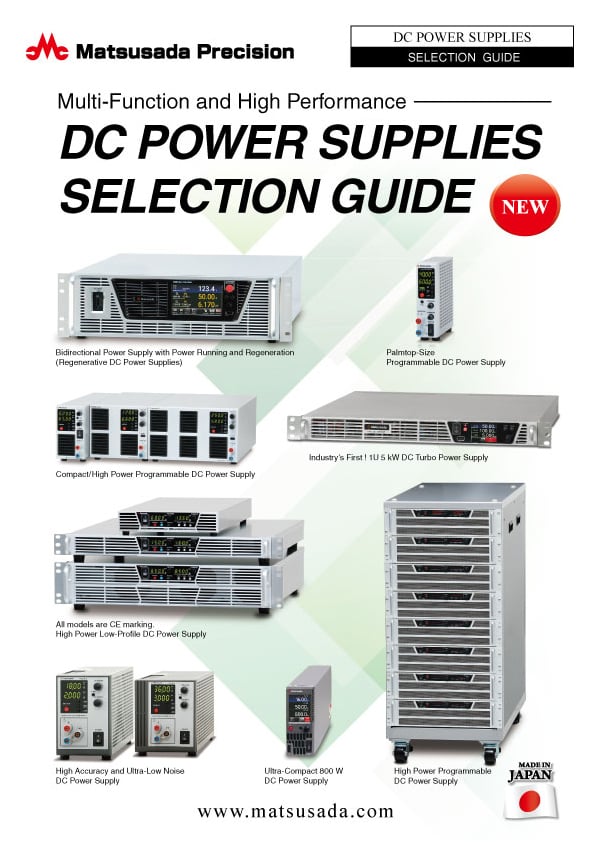

DC POWER SUPPLIES SELECTION GUIDE

Date: 2024-09-26 rev.01

PDF (1,202 KB)

-

How to Use DC Power Supplies

Date: 2024-03-05 rev. 08

PDF (1,467 KB)

-

Application package manual

Date: 2024-4-4 rev.2.3

PDF (2,227 KB)

-

Command List (PRT, PRKT, PBR, PKTS series)

Date: 2024-08-27 rev 0.2

PDF (897 KB)

Login Required

-

PRTM series Datasheet

Date: 2024-10-10 rev.20

PDF (5,282 KB)

-

DC POWER SUPPLIES SELECTION GUIDE

Date: 2024-09-26 rev.01

PDF (1,202 KB)

-

How to Use DC Power Supplies

Date: 2024-03-05 rev. 08

PDF (1,467 KB)

-

Application package manual

Date: 2024-4-4 rev.2.3

PDF (2,227 KB)

-

Command List (PRT, PRKT, PBR, PKTS series)

Date: 2024-08-27 rev 0.2

PDF (897 KB)

In this website, we provide only the latest version of information including instruction manuals as of our products. Therefore, the newest versions of manuals on the website might be not same as the ones of products you purchased in the past.