Looking around the world, there are many areas where sanitary water is not always available, and clean water technologies are attracting attention. In addition, pure water, free of admixtures, is indispensable in semiconductor manufacturing, precision equipment cleaning, and chemical product manufacturing. This article will introduce you to water treatment methods and more.

What is Water Treatment?

Water treatment is the process of removing impurities from water. Not only water that looks dirty, but even water that looks clean contains a variety of impurities. Impurities can be broadly divided into the following five categories

Foreign element

It is so-called garbage. Dust, clay, iron sand, etc., mixed with water.

Aquatic organisms

This includes living admixtures such as bacteria and microorganisms.

Organic substances

It is an organic substance dissolved in water. Algae and trees decomposed by microorganisms, organic detergents, organic fertilizers, etc.

Inorganic salts

They are inorganic salts dissolved in water. In addition to water hardness components such as calcium, salt, and iron.

Gas

Various gases are dissolved in water for reasons such as taking in gases from the air while it is in contact with the air. Examples include carbon dioxide, oxygen, and hydrogen sulfide.

Water treatment is the process of removing the above impurities to obtain water for a specific purpose.

Purpose of Water Treatment

There are three main types of water treatment objectives.

Clean dirty water before returning it to nature (sewage treatment)

Wastewater purification process. It removes substances and foreign substances that are harmful to nature from factory effluent and domestic wastewater.

Making water for domestic use from river water and groundwater (water purification treatment)

River water and groundwater also contain various impurities. It removes bacteria and harmful substances from water to produce drinking and safe water for daily use.

Industrial

In some cases, industrial applications require water with even fewer impurities than domestic water, known as pure water. One of the industrial water treatment processes is carried out to obtain this pure water.

Ultrapure water with particularly few impurities is produced for industrial use, which is used for manufacturing semiconductors and precision machinery.

Sewage purification is the largest and most familiar volume of water treatment. To create domestic water, river water is treated at water purification plants, and seawater is desalinated.

Water treatment methods

Water treatment methods can be divided into two main categories.

Physicochemical treatment

Physicochemical treatments can be divided into two categories: physical and chemical. Physical treatment is a method of separating impurities by physical characteristics such as the size and specific gravity of the pollutant. Chemical treatment is a treatment method in which impurities are separated by chemical properties. Each process involves the following techniques

Physical treatment: sedimentation and flotation separation, filtration

Chemical treatments: ion exchange, oxidation (ozone), electrodialysis, electrolysis

Biological Treatment

Biological treatment is a method of using microorganisms such as bacteria to utilize the action of decomposition or conversion by microorganisms, or to destroy pathogenic organisms. The so-called aeration tanks used to treat sewage are another typical example of biological treatment. Biological treatment also includes the treatment of organisms in water, such as the sterilization of pathogens.

Evolving Water Treatment

The development of the semiconductor and precision machinery industries has led to growth in demand for ultrapure water used in these industries. With it, water treatment technology has also evolved. Here are three relatively new water treatments.

RO Membrane

RO membranes, also called reverse osmosis membranes, are a method of water treatment. When salt water and fresh water are put in between a semipermeable membrane, the freshwater passes through the membrane and moves to the saltwater side. Osmotic pressure then occurs on both sides of the membrane.

However, if pressure greater than the osmotic pressure is applied to the saltwater side, reverse osmosis occurs, and water moves from the saltwater side to the freshwater side. This method was originally used to desalinate seawater to make freshwater, but has recently been used in the ultrapure water production system and water recovery fields.

Ion exchange

Electro-deionization is also known as EDI. It is operated as a module consisting of multiple membranes.

The EDI module has a structure in which cation and anion exchange membranes are alternately arranged, sandwiched between anodes and cathodes, and the gaps between them are filled with ion exchange resin.

When a direct current is applied between the anode and cathode, anions such as chloride ions move to the anode, and cations such as sodium ions move to the cathode. Cation-exchange and anion-exchange membranes are structured to allow only cations and anions to pass through, respectively.

Therefore, the ionic concentration and dilution compartments will be configured between the exchange membranes. The system collects water that has passed through this dilution compartment to obtain pure water. During operation, the ion exchange resin must be replaced periodically.

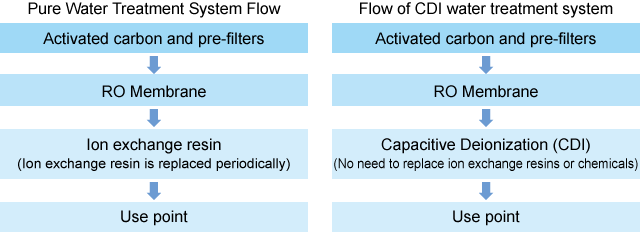

CDI

CDI (Continuous Deionization) is the name of a water purification system licensed by IONPURE® in the United States. The power of electricity moves ions in water to obtain pure water. It is an innovative technology because it does not use chemicals and does not require periodic replacement of ion exchange resins.

CDI is used primarily in the manufacture of pharmaceuticals and semiconductors.

EDI and CDI are electro-deionization technologies that use a direct current power source to produce pure water continuously. The advantage is that no chemicals are used, so there is no need for wastewater treatment. Ion exchange membranes used in EDI and CDI are also used in metal recovery applications as well as in the production of pure water.

The voltage and current of the DC power supply used for EDI and CDI vary depending on the size of the ion exchange membrane, but the voltage is generally 300V to 500V, and the current is several A to 10A. The DC power supply is currently used in constant current (CC: Constant Current) mode.

Matsusada Precision's DC power supplies are used in these water treatment applications.

Reference (Japanese site)

-

栗田工業株式会社

水処理とはなにか https://kcr.kurita.co.jp/wtschool/002.html

逆浸透現象を利用したRO膜 https://kcr.kurita.co.jp/wtschool/008.html -

セイスイ工業株式会社 水処理とは?種類や仕組みの基礎知識を解説

https://seisui-kk.com/column/ew4k9j5kz -

室町ケミカル EDIの基礎知識

https://www.muro-chem.co.jp/media/knowledge/edi

Recommended products

We, Matsusada Precision, provide solutions for DC power supplies for EDI and CDI processes in water treatment.