Basics of Thermoelectric Cooling

Thermoelectric coolers use the Peltier module, a semiconductor-based electronic component. Conventional vapor compression heat pumps (compressors) have been used for cooling solutions.

The compressor-based cooling involves a complex system where the refrigerant enters the compressor as a low-pressure gas. The gas is cooled to a high-pressure liquid refrigerant and converted into a low-pressure liquid. The pressure reduction lowers the temperature. Compressor-based heat pumps are widely used in many applications, including air conditioners and refrigerators.

On the other hand, the thermoelectric cooling system comprises semiconductor-based electronic components of an effortless mechanism. Another key feature is that it can provide both cooling and heating with a simple reversal of the current.

Moreover, the heat pumped by the thermoelectric cooler assembly that is a compressor-based solution is provided as heat. Air conditioners utilizing thermoelectric coolers have significant advantages over compressor-based systems. However, the compressors tend to be heavier and larger than comparable thermoelectric-based systems.

What is Peltier Element?

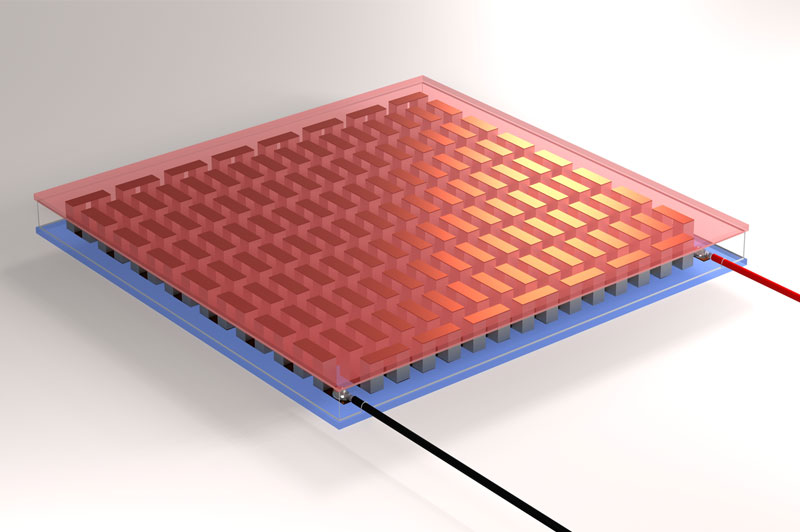

Peltier element that is used in thermoelectric cooling is a semiconductor-based electronic component. When the DC flows in a certain direction, a large amount of heat is dissipated by the heat sink for a low amount of heat absorbed (cooled) at the cold side of the Peltier element.

In 1834, a French physicist Jean Charles Peltier discovered the "Peltier effect". He found that if you take a thermocouple and apply a voltage, this causes a temperature difference between the junctions. This results in a small heat pump, later referred to as also known as a thermoelectric cooler (TEC). However, in the 1950s, when semiconductors were widely used, they were put to practical use.

Peltier Effect

Before learning about the Peltier effect, we should know more about the Seebeck effect.

The Seebeck effect is the electromotive force induced by the temperature difference (gradient) between the two ends of a material. When heat is applied to one of the two, the applied temperature gradient causes the material's charge carriers (negatively charged electrons or positively charged holes) to diffuse from the hot side to the cold side.

If only one of the materials is heated, no carriers are generated at the other end, so carriers move from the hot side to the cold side to equilibrate internally. This is the electromotive force due to the Seebeck effect.

This Seebeck effect is also used in thermocouples. The Seebeck effect occurs in all materials but is stronger in some semiconductor materials. Connecting material having electrons in series with another material having holes will increase the output voltage.

In other words, the structure is the same as P-type and N-type semiconductors connected in series. Connecting the P-type and N-type semiconductors alternately in series will increase the output voltage. That is, the Seebeck effect is responsible for the thermocouples.

The Peltier element is the opposite of the Seebeck effect in principle. When an electric current is applied to a material, heat is generated at one end and absorbed at the other to balance the carriers. The feature provides the reversible process of cooling and heating by reversing the direction of the current.

Like the Seebeck effect, it occurs in all materials, but heat absorption and generation are particularly efficient in those connected in the order of N-type semiconductors, metals, and P-type semiconductors. When no current is flowing, the Fermi distribution function distributes free electrons in the metal between the P-type and N-type semiconductors.

However, the Fermi distribution is soft when current flows there and the temperature drops.

Advantages of Peltier Elements

Peltier elements offer advantages as follows.

- Reversing the polarity will switch to a heating or cooling system.

- Excellent temperature response

- Accurate temperature control

One of the critical features of Peltier elements is that heating as well as cooling is available by changing the electricity flow direction. The current direction and values can be precisely tuned, and the temperature can be accurately controlled. The element directly absorbs and generates heat using a small number of mechanical components, making work more efficient and contributing to energy conservation.

Thermoelectric Peltier Module vs. Heat Pump (Vapor Compressor)

- No refrigerants or greenhouse gases such as chlorofluorocarbons are required.

- Quiet and free of vibrations

- Small size with fewer components

- Peltier modules have a lower output than Heat pumps.

Heat generators use electricity to drive the vapor compression cycle of refrigerants where they compress for heating and decompress for cooling. In the past, however, chlorofluorocarbon gases were used as refrigerants, which significantly impacted the environment and directly related to ozone layer depletion and global warming. Chlorofluorocarbon substitutes started to be used as a replacement, but they are still a source of ozone depletion and global warming.

Utilizing thermoelectric coolers (TECs) to avoid using harmful refrigerants helps prevent such environmental destruction. Furthermore, the thermoelectric devices are quiet and free of vibrations since no compressors or motors are required. The element directly absorbs and generates heat using a small number of mechanical components, making the unit small and lightweight.

However, Peltier devices often have a lower output than heat pumps, and the heat pumps are superior in a large-scale cooling and heating system.

Applications of Peltier Modules

Peltier modules are mainly used in three fields: Lifestyle, Measurement, and Medication.

Home Appliances

- Small refrigerators

- Cooling CPU/GPU computers

- Wearable air conditioners

The Peltier modules featuring compact, no electrical noise and vibration can be used for small refrigerators in hotel rooms, etc. They are also used to cool CPUs and GPUs in electronic devices such as computers that generate heat.

In addition, demand has grown in recent years in wearable air conditioners. To prevent heat stroke, wearable air conditioners in clothing using Peltier modules are used to cool down the human body. They are compact and lightweight and can stably operate for a long time even with power from a battery.

Test and Measurement

- Cooling sensors and laser oscillators in measuring equipment, etc.

- Electrical Control Panel Cooling

- Heating and cooling of temperature chambers

The thermoelectric Peltier modules provide various test and measurement applications such as X-ray, electron, infrared, ultrasonic, and imaging detectors. They can prevent them from detecting thermal noise. The thermoelectric coolers are small and do not generate vibration, they are suited to precision machinery cooling such as laser oscillators to cool the oscillation area.

Using double or triple-layered Peltier elements makes stronger cooling down to the -10°C range possible. Moreover, featuring precise temperature control, the Peltier modules are used in cooling electrical control panels, heating and cooling temperature chambers, etc.

Medical Equipment

- Thermal cycler for PCR

Peltier modules are utilized in modern medical technologies like a thermal cycler (also known as a thermocycler, PCR machine or DNA amplifier) and real-time PCR (RT-PCR) system. The instruments effectively perform accurate PCR testing with rapid heating and cooling, precise temperature control, high stability, wide setting range, etc.