What are Micro-CT Scanners?

A micro-CT scanner is an advanced imaging tool used for nondestructive inspection of internal structures at a microscopic level. It employs microfocus X-ray sources to create high-definition X-ray images, even at high magnifications, enabling the production of Highly accurate computed tomography (CT) images.

These scanners utilize a cone-beam CT configuration, where the object is positioned on a rotating turntable, and X-rays are emitted from the side. The images from the X-ray are captured at different angles and reconstructed by a high-performance computer to produce detailed CT images as the object rotates rapidly.

The reconstructed CT data is further processible and visualized using dedicated software, allowing tomographic and three-dimensional images to be created. This software also enables precise measurements, cross-sectional displays, and even reverse engineering of the scanned objects.

Matsusada Precision offers a range of micro-CT scanners designed for various industries and applications. These scanners are equipped with Matsusada Precision's proprietary microfocus X-ray technology, allowing one to visualize minute internal structures in multiple materials.

Types of Micro-CT Scanners

Micro-CT scanners are diverse, offering various capabilities to suit research and industrial needs. These scanners can differ in resolution, sample size accommodation, speed, and imaging modes. Understanding the types of micro-CT scanners can help select the most suitable one for specific applications.

By Industry

Micro-CT scanners are used broadly in various industries, offering valuable insights into the internal structures of materials and products without causing damage. They are primarily classified into two categories: industrial and medical micro-CT scanners.

Industrial micro-CT scanners

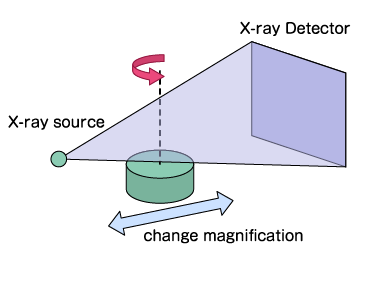

Industrial micro-CT scanners are instrumental in quality inspection, materials evaluation, and reverse engineering in industrial settings. Unlike medical CT scanners, industrial CT scanners do not pose radiation exposure risks to operators. These scanners typically feature fixed X-ray tubes and detectors, with the product on a rotatable stage to facilitate imaging.

Industrial micro-CT does not expose you to radiation so that it can take images at high doses. Matsusada Precision's X-ray CT scanning system is tailored for industrial applications, offering several high-voltage power supplies designed for X-ray tubes used in industrial CT inspection systems.

Medical CT scanners

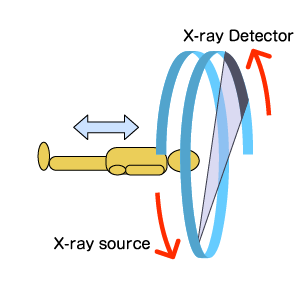

In contrast to industrial types, medical CT scanners prioritize minimizing radiation exposure during X-ray examinations of the body. These scanners use rotating X-ray tubes and detectors to capture body images, minimizing blurring quickly. The exposure is brief despite the high radiation dose used for these examinations. Medical CT scanners are crucial for diagnostic imaging, providing detailed anatomical information for medical professionals.

Both types of CT scanners play a pivotal role in advancing scientific research, industrial processes, and medical diagnostics, showcasing the versatility and importance of this technology in various industries.

by Placement method

Micro-CT scanners can be categorized based on their placement method, which refers to how the scanner is designed and positioned in relation to the sample. The two main categories are benchtop and floor-standing scanners.

Benchtop micro-CT scanners

Benchtop micro-CT scanners are compact, user-friendly systems for smaller samples and lower X-ray energy applications. These scanners are typically less expensive, easier to maintain, and require less space than their floor-standing units.

However, their X-ray energy is limited, usually up to 130 kV, which may restrict the types of samples and applications they can accommodate. Benchtop scanners are ideal for academic research, quality control in small industries, and educational purposes.

Floor-standing micro-CT scanners

Floor-standing micro-CT scanners are larger, more powerful systems for imaging larger samples and utilizing higher X-ray energies. These scanners offer higher resolution and accommodate a broader range of sample sizes and densities.

They are often used in industrial applications, such as material science, geology, and biology, requiring high-resolution imaging of larger samples. However, they are more expensive, require more maintenance, and take up more space than benchtop models.

By X-Ray Energy

Micro-CT scanners can also be classified based on the X-ray energy they use for imaging. The two main categories are high-energy and low-energy scanners, each suitable for different samples and applications.

High-energy micro-CT scanners

High-energy micro-CT scanners utilize X-ray energies ranging from 160 kV to 225 kV, or even higher in some cases, and are suitable for imaging larger and denser samples, such as metals, ceramics, and geological specimens. These scanners often use an open-type microfocus X-ray tube, which offers high resolution and is commonly used in industries like aerospace, automotive, and electronics, as well as in scientific research.

They offer excellent penetration power and can provide detailed images of internal structures with high spatial resolution. These scanners are capable of high magnification and can be applied to a diverse range of inspection objects. Used predominantly in industrial applications for quality control, failure analysis, and research and development, high-energy micro-CT scanners come with a significant cost. Additionally, they require regular maintenance and are complex to operate, demanding specific technical skills such as knowledge of vacuum systems.

Low-energy micro-CT scanners

Low-energy micro-CT scanners use X-ray energies below 150 kV and are suitable for imaging lighter materials such as plastics, polymers, light metals, and biological samples. In particular, low-energy X-rays are called soft X-rays, and low-energy micro-CT scanners are also referred to as soft X-ray 3D microscopes. These scanners typically employ a closed microfocus X-ray tube, which is designed to produce a small focal point, preventing blurring of X-ray images and delivering sharp, enlarged images.

This type of micro-CT provides good contrast for soft tissues and offers high-resolution imaging of small, delicate structures. Microfocus X-ray sources, specifically developed for 2D and 3D nondestructive testing, play a crucial role in achieving these imaging capabilities.

Low-energy micro-CT scanners are relatively inexpensive and compact imaging devices, making them ideal for biomedical research, pharmaceutical development, and materials science. These scanners specialize in high-resolution imaging of small, low-density samples and are known for their low maintenance requirements and ease of operation. Matsusada Precision exclusively sells this type of product, catering to the needs of various scientific and industrial sectors.

By Scanning Target

Micro-CT scanners are classified into two main categories based on their scanning target. These categories are detailed below:

In Vivo micro-CT scanners

In vivo micro-CT scanners are designed to scan live specimens, primarily small animals like mice, rats, and sometimes rabbits. These scanners allow for longitudinal studies, where the same animal can be scanned multiple times to observe changes. It is beneficial in studying the effects of treatments like drugs, diet, or hormonal interventions on the weight of the body, growth of bone, tumors, and other physiological aspects.

In vivo scanners are also used to analyze health concerns like chronic obstructive pulmonary disease (COPD), where breathing monitoring is required. They can also be a reference for registration with other imaging modalities like micro-PET or micro-SPECT scans.

Despite some resolution tradeoffs, in vivo scanners can scan longer objects than ex vivo systems due to their scanning geometry. The structure is a miniaturized version of a medical CT scanner.

Ex Vivo micro-CT scanners (Industrial micro-CT scanners)

These CT scanners are used to scan samples that are no longer alive or have been excised by living organisms. These scanners are ideal for endpoint studies focusing on specific areas of interest, such as lungs, bones, tumors, implants, and grafts. They are also suitable for biomaterial studies, studies for comprehension, studies materials, implantation involving big animals, and more.

Ex vivo scanners offer scan times that are longer (as there's no concern for the live sample's dose), greater spatial resolution, and enhanced signal-to-noise ratios. As a result, the image quality is also better. They are commonly used for applications requiring fine details, such as trabecular bone imaging for osteoporosis, vascular disease imaging in various organs, and cartilage wear models.

Ex vivo scanners can also be used to study biomaterials, larger animal implants, food and seed structures, anthropological studies, rock core samples, and other applications.

Matsusada Precision Micro CT Scanners

Matsusada Precision offers a range of high-quality Micro CT Scanners, each designed for specific applications and requirements. Here is an overview of some of the products offered:

Benchtop X-Ray CT Scanner - precision µB4500

The Benchtop X-Ray CT Scanner, like the precision μ B4500, is ideal for radiography powder, liquid, and other substances in the rotation stage. Its horizontal design is particularly suitable for samples that are challenging to image using traditional vertical systems, as it provides more stable imaging.

The system offers high-resolution imaging with advanced artifact reduction functions, making it ideal for mixed-material samples. Its compact size makes it suitable for use in small offices, space-constrained factories, and laboratories.

- Key Features:

-

- Suited for radiography of powder, liquid, etc., on the rotation stage

- Ideal for samples that have difficulty in radiography and tomography

- Horizontal radiation system for more accessible and more stable CT object imaging

- Specifications:

-

- Radiation Type: Horizontal

- Application: Radiography of powder, liquid, etc.

- Rotation Stage: Yes

- Imaging Stability: High

- Applications:

-

- Material Science: Powders, liquids

- Pharmaceuticals: Tablet inspection, liquid encapsulation

- Electronics: Small components

X-ray Micro-CT Scanner - precision CT9600

The X-ray Micro-CT Scanner, such as the precision CT9600, is designed for high-speed, high-resolution X-ray microtomography. It offers easy scanning for optimal tomography, increasing work efficiency with fast scanning times.

The system features various functions for enhancing image quality, such as artifact and metal artifact reduction. It also includes an intuitive user interface for easy operation and safety features like interlock and emergency stop systems.

- Key Features:

-

- High-resolution and high-speed scanning

- Easy scanning for optimal tomography

- Enhancing image quality with various functions

- Specifications:

-

- Resolution: High

- Speed: High-speed scanning

- Operation: Intuitive

- Defect Detection: Facilitated

- Applications:

-

- Material Science: Porous materials, composites

- Life Sciences: Small organisms, biological samples

- Geology: Rock samples, mineral studies

X-ray Inspection System with Optional CT Function

The X-ray Inspection System with Optional CT Function, like the µRay8700/µRay8760, is a high-performance system for nondestructive inspection. It features a high-power X-ray tube and a high-resolution X-ray camera for clear images.

The system offers high transmission for CT scans, allowing for easy observation of the entire object. It includes exclusive noise reduction technology and a small focal spot size for high-quality imaging. The system also comes with software for image processing and analysis, making it easy to use for anyone.

- Key Features:

-

- High transmission with 130kV X-ray tube voltage and 40W output power

- Exclusive noise reduction technology

- Smallest focal spot size of 5 µm with 4 W output

- Specifications:

-

- Transmission: High

- Tube Voltage: 130kV

- Output power: 40W

- Focal spot size: 5 µm

- Applications:

-

- Electronics: PCB inspection, semiconductor analysis

- Automotive: Component inspection, battery examination

- Aerospace: Composite material testing, defect detection

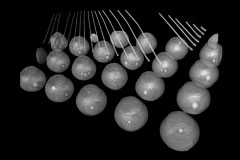

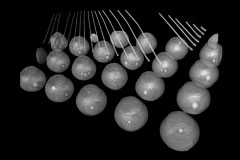

Scanning Examples by Matsusada Precision Micro CT Scanners

Matsusada Precision's micro-CT scanners offer cutting-edge imaging capabilities for various applications. From detailed analysis of biological samples to quality control in industrial settings, these examples showcase how Matsusada Precision's micro-CT scanners provide invaluable insights across different fields.

Electronics

BGA

Cable

Automobile

Motor

Battery

Foods & Drugs

Beer can

Tablet (pharmacy)

Healthcare

Box lid of wet wipes

Brush type eyeliner

FAQs about Micro CT Scanners

What Is the Difference Between micro-CT and CBCT?

Micro-CT (micro-computed tomography) and CBCT (cone-beam computed tomography) are both imaging techniques that use X-rays to create detailed 3D images of objects or specimens. However, they differ in several key aspects:

-

Resolution: Micro-CT refers to the high resolution of the images produced, with pixel sizes as small as 100 nanometers. In contrast, CBCT uses the scanning principle, and its resolution is typically not as high, with pixel sizes ranging from around 200 micrometers to a few millimeters.

-

Sample Size: Micro-CT is suitable for imaging small to medium-sized samples with diameters up to 200 millimeters. CBCT, on the other hand, is often used for larger objects, such as human patients in dental or medical applications.

-

Applications: Micro-CT is commonly used in scientific research and industrial applications to study the internal structure of materials, biological samples, and tiny organisms. CBCT is a technical term used within the industry, primarily in medical and dental fields, to image bones, teeth, and soft tissues in patients.

-

Image Quality: Due to its higher resolution, micro-CT produces images with greater detail and clarity than CBCT. It makes micro-CT more suitable for analyzing delicate structures and features within samples.

-

Cost and Complexity: Micro-CT systems tend to be more expensive and complex than CBCT systems, partially due to the higher resolution and precision required for micro-CT imaging.

In summary, while micro-CT and CBCT are valuable imaging techniques, they are used in different contexts based on the size of the sample, the required resolution, and the specific application.

What Are The Advantages Of Micro-CT?

Micro-CT provides high-resolution 3D imaging, preserving samples for future studies without cutting. It offers quantitative information and allows studying internal structures, porosity, and more in various materials and biological samples.

What Are The Uses Of Micro-CT?

Micro-CT is used for failure analysis, quality control, and reverse engineering, offering detailed 3D imaging of internal structures in various materials and biological samples.

What Is The Difference Between Micro-CT and CT Scan?

Micro-CT offers higher resolution imaging on a smaller scale than CT scans, allowing for detailed analysis of internal structures in small samples.

Can Micro-CT Also Take Measurements?

Yes, Micro-CT can take measurements and provide quantitative data on parameters such as porosity, structure, density, etc.

How Much Detail Can Be Seen With Micro-CT?

- Micro-CT provides:

- • Exceptional detail.

- • Capturing features as small as 100 nanometers.

- • Enabling the visualization of intricate internal structures.

What Is The Measurement Procedure for Micro-CT?

The measurement procedure involves scanning the sample using X-rays, reconstructing the data into 2D cross-sectional slices, and analyzing the resulting 3D images.

Do I Need To Be Qualified To Operate It?

While specific qualifications may vary, operating Micro-CT requires safety knowledge, training in its usage, and an understanding of radiography imaging techniques.

Are CT Images In Color?

CT images are typically grayscale, representing variations in density, but they can be false-colored for enhanced visualization or analysis.