Contains DC power supply know-how and how-to-use!

Matsusada Precision is the leader in power supply manufacturing

PROPER INSTALLATION OF POWER SUPPLY

Proper installation of the power supply is essential for your own personal safety and the longevity of the power supply.

Condition of installation

- Place the power supply's main body horizontally on a flat, smooth, stable surface.

- Do not use the power supply in an environment with excessive dust or corrosive gas.

- Be sure your power supply has proper ventilation. Do not install your power supply in an enclosed space where exhaust heat from the power supplies' exhaust vents is blocked.

- Be sure to install your power supply in a dry area.

How to install

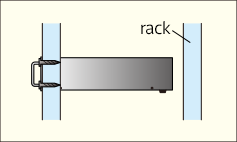

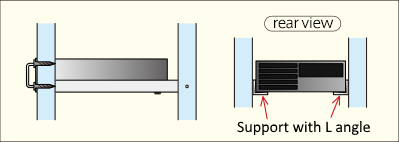

When mounting your power supply into a rack, please be certain that your power supply has adequate support. This can be done either with heavy-duty sliding rails or L-shaped support angles mounted below the power supply.

Not Good

Insufficient Support

Good

With Support Angles

Lifetime

The lifetime of a power supply can be shortened by up to 50% of normal conditions when the environmental temperature increases only 10°C.

(The power supply lifetime listed on the datasheet is based on an environmental temperature of about 20°C.)

STOP!

Environmental Conditions that Could Shorten the Lifetime of Your Power Supply

HEAT

Narrow spaces or enclosures tend to trap heat and can shorten the lifetime of your power supply. When air-inlets or exhaust vents are obstructed, the temperate inside the power supply increases dramatically and the lifetime of the power supply is reduced.

Space for radiation shall be more than 4" from air intake, and 12" from exhaust holes.

DUST

When a power supply is installed in a dusty environment or too close to the floor, it causes the accumulation of dust inside the power supply which results in deficient performance and a reduced lifetime.

CONNECTION OF LOAD

Your power supply's stability and ripple noise will be directly affected by its wiring and grounding.

• Use wires thick enough for your application. Use as short a length as possible.

• Select PVC electric wire (105°C) of the proper voltage rating

Current curring capacity of electric wire, maximum length limited by maximum voltage compensation by remote sensing (0.5V/each way) have to be considered when connecting to the load. See below table to determine the proper gauge of the wire.

| AWG | mm2 | Max. current [A] |

|---|---|---|

| 18 | 1.1 | 2 |

| 16 | 1.3 | 7 |

| 14 | 2.1 | 11 |

| 12 | 3.3 | 18 |

| 10 | 5.3 | 23 |

| 8 | 8.4 | 39 |

| 6 | 13 | 67 |

| 4 | 21 | 106 |

| 2 | 33 | 170 |

| 1 | 42 | 209 |

| 1/0 | 53 | 270 |

| 2/0 | 67 | 330 |

| 3/0 | 85 | 350 |

• When connecting multiple loads in parallel, connect to each load

Good

Proper Connection

Not Good

Improper Connection

There will be a larger voltage drop at loads 2 and 3. The ripple at those loads will also increase due to the current of each load.

• When connecting to a dielectric load, use a diode with a rating larger than the output voltage and current of the power supply as shown in the diagram below. This diode will protect the power supply from a voltage kickback from the load.

• Connecting a circuit that involves discharge or short circuit may shorten the service life of the product and cause it to fail. When connecting to a circuit where discharge or short circuit may occur, install a protective resistance at the output.

CORRECT WAY TO MEASURE VOLTAGE

Taking into consideration that the power supply is used to apply the voltage to the loads since the power supply feature can detect the voltage, it is important to accurately measure the voltage. The remote sensing function of DC power supplies is used to accurately measure the voltage applied to the loads. The voltage drops can be compensated on connectors or wiring.

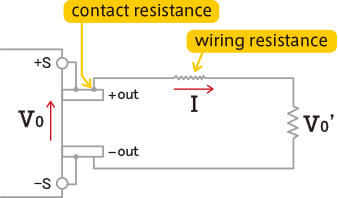

How Remote Sensing Work

A voltage drop will occur when current flows over resistance of connectors or wires.

V0' = V0 - (Contact resistance + Wiring resistance) x I

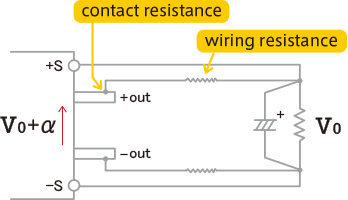

When connecting the remote sensing wires to the load to compensate for voltage drops, the power supply will gain output in order to sustain the set voltage.

Caution

Please check the following points of using remote sensing.

Caution

Please check the following points of using remote sensing.

- The impedance of the sensing wire is high. Use a twisted pair or shielded wires so that they are not affected by surrounding circuitry or wiring.

- Placing an aluminum electrolytic capacitor at the sensing point often works better for stable behavior. The recommended capacitance of aluminum electrolytic capacitors is 0.1 to several hundred µF with a voltage rating of larger than the rated output voltage.

Additionally, in order to measure the voltage more precisely, a digital multimeter is available by connecting. The setting voltage of DC power supply needs to be arranged to obtain the voltage measurement of the multimeter.

CONNECTION OF MULTIPLE POWER SUPPLY TO OUTPUT

Series Operation

When connecting multiple power supplies in series, make sure the maximum output voltage on the instruction manual of each model.

When the master/slave function is to be used, follow the directions in the instruction manual.

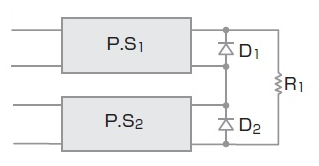

Good

Connect as shown in the diagram above. Select diodes for D1 and D2 with a high enough voltage rating in the opposite direction and a current rating in the same direction as the rated output of the power supply.

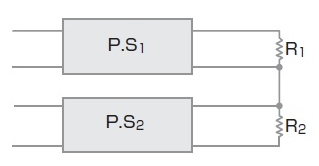

Good

The connection diagram above may also be used. When controlling each power supply with an external voltage source, take note that the potential of the control voltage should be changed.

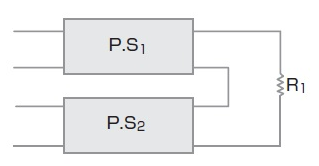

Not Good

The connection depicted in the diagram above may not work. Due to the slight difference in the speed of each supply, current flowing from one power supply might cause constant current mode in the other supply and cause a shut-down.

Parallel Operation

When connecting multiple power supplies in parallel, balancing of the current is required because of the different output voltage between the power supplies.

- When the master/slave function is to be used, follow the directions in the instruction manual.

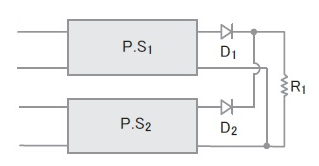

Good

Connect as shown in the diagram to the left. Balance the current using diodes for D1 and D2 in the manner depicted. Consider the voltage rating of the diodes, the current, and the lower loss caused from heat.

Related Technical Articles

Recommended products

Matsusada Precision's high-performance DC power supplies