Sputtering is one of the coating methods of Physical Vapor Deposition (PVD) that can produce a thin film metal coating on the surface of a material by physical effects.

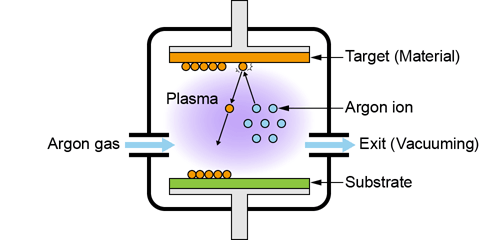

It involves introducing a controlled gas, such as argon, and a material which is called the target for thin film coating. When a negative voltage is applied to the target to generate a glow discharge, the inert gas plasma impinges on the target surface at high speed.

Then, the atoms are sputtered out of the target. This process is called sputtering; the ejected atoms vigorously adhere to the substrate.

Sputtering is one of the most efficient systems to obtain film thickness distribution, and it has the ability to control film quality and thickness with high precision. The sputtering deposition is suitable for high-melting-point metals and alloys, and it can also create a thin, precise coating of oxides and nitrides by using a reactive gas.

The sputtering method has many applications in semiconductor wiring, barrier films, and transparent conductive films used for smartphones and tablets. It also provides beautiful appearance processing for car headlight reflectors and decorative films.

- Related words:

-

- Physical Vapor Deposition (PVD)

- Plasma

- Semiconductor

- Flat Panel Display (FPD)

- Thin film

- Sputter

- High voltage

Recommended products

There are two methods of sputtering: a DC (direct current) power supply for sputtering and an RF (radio frequency) power supply. Both DC and RF can be used for metal targets for sputtering deposition. However, when using insulators as targets, it is necessary to use a high-frequency power supply for sputtering because no discharge occurs with DC. Matsusada Precision's standard products take no countermeasures against arc handling and abnormal discharge for sputtering. Customers who intend to use these products for sputtering applications should contact our sales office in advance.

Matsusada Precision offers power supply solutions for vacuum and deposition process applications. We also manufacture other products, such as electrostatic chucks and piezo drivers in semiconductor and FPD manufacturing equipment.

Information on related articles in Technical Knowledge

- Front-End Semiconductor Manufacturing Process

- Back-End Semiconductor Manufacturing Process

- The manufacturing process of FPD

- Plasma in semiconductor manufacturing

- Types of Power Semiconductors -Reliability and Performance Test

- What is a power inverter? (Basic knowledge)

- Safety and Usage of High Voltage Power Supply