Nondestructive Testing is a group of analysis techniques used to evaluate the properties of a material, component, or system without causing damage. Methods such as X-ray radiography and ultrasonic testing direct energy into an object. The resulting images (from X-rays) or echoes (from ultrasound) are then analyzed to detect internal flaws and deterioration.

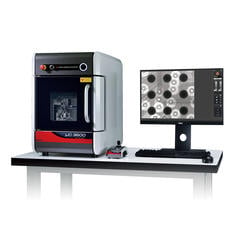

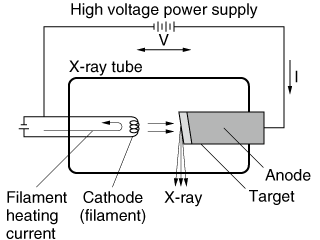

X-ray inspection systems use an X-ray tube as the radiation source. During an inspection, X-rays from the tube are projected through the target object, and a transmitted image is captured by a detector, such as a Flat Panel Detector (FPD). These images are then analyzed to identify internal defects, corrosion, and other forms of deterioration.

Ultrasonic testing (UT) employs an ultrasonic transducer. This device contains a piezoelectric element that vibrates when a high-frequency voltage is applied, generating ultrasonic waves. These waves are transmitted into the object under inspection, and the resulting reflected waves (echoes) are measured to detect internal flaws.

Matsusada Precision provides a comprehensive range of solutions for nondestructive testing. Our offerings include complete X-ray inspection systems, as well as critical components such as high-voltage power supplies for X-ray tubes and high-frequency power supplies for driving piezoelectric elements.

- Related words:

-

- Radiographic Testing (RT)

- Ultrasonic testing (UT)

- Eddy-current

- Magnetic-particle

- X-ray

Recommended products

Matsusada Precision offers a wide range of nondestructive testing equipment, including X-ray nondestructive testing equipment, high-voltage power supplies for X-ray tubes, and high-frequency power supplies for driving piezoelectric elements.

Information on related articles in Technical Knowledge

- Non-Destructive Testing: Types and Applications

- What are X-rays? (Basic Knowledge)

- How to Choose an X-ray Inspection System

- Principles of Radiography

- How to use X-ray Inspection System safely

- What is the difference between Radioactivity, Radiation, and Radioactive Materials?

- Understanding Radiation: Effects on the Body and X-ray Safety

- What is Microfocus X-ray? (Basic Knowledge)

- Basics and Principles of Computed Tomography (CT)

- How to Acquire High-Quality Computed Tomography (CT) Images - X-ray NDT series (1)

- A Guide to X-ray CT Images: Formats, Viewing, and Applications - X-ray NDT series (2)

- X-ray Image Processing and Automated Inspection - X-ray NDT series (3)

- Types of X-ray Tubes and High-voltage Power Supplies

- What is X-Ray Fluorescence? (Basic Knowledge)