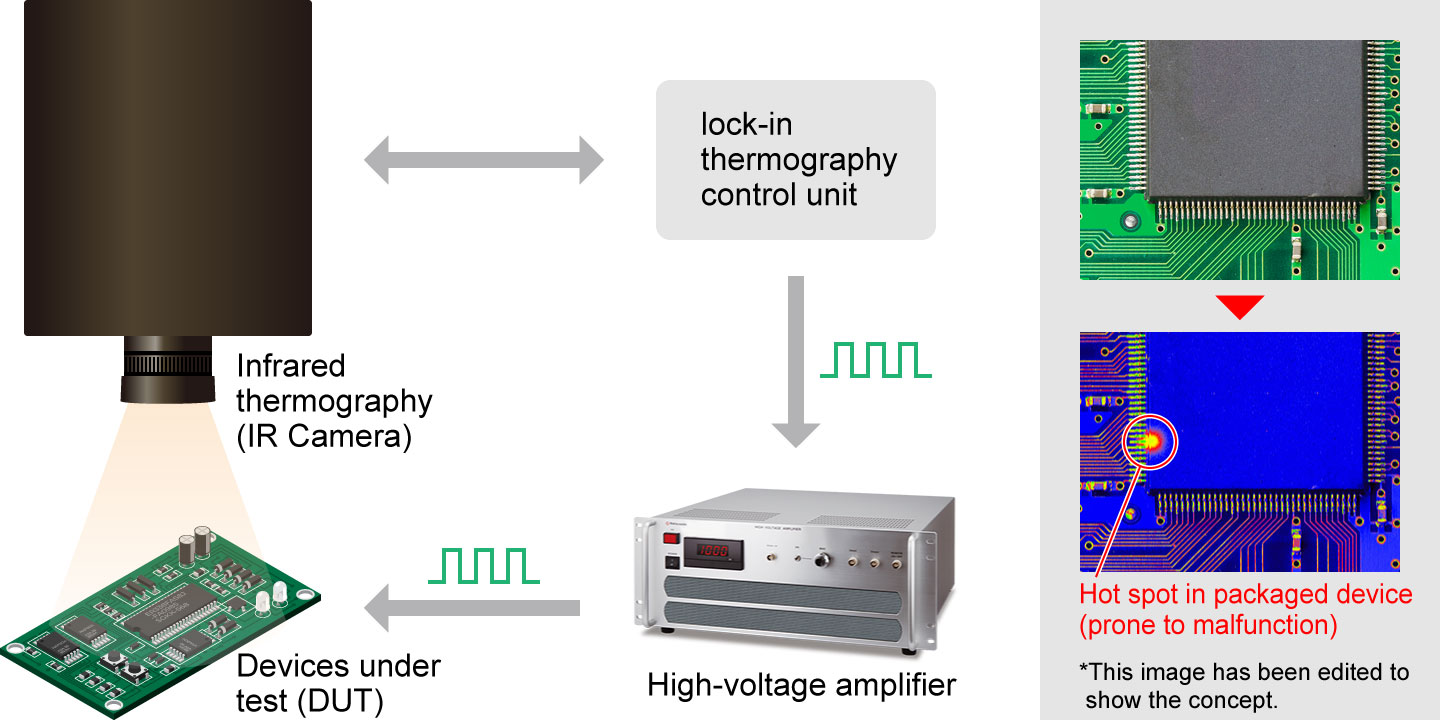

Lock-in Thermography (LiT) is an advanced analytical technology that applies pulses of cyclic electrical energy to semiconductor device packages, printed circuit boards (PCBs), and other test targets to detect defects and abnormalities based on localized heat generation (hot spots). Detecting slight temperature changes, which is impossible with conventional infrared thermography, allows for faster localization of defects. Lock-in thermography synchronizes the image acquisition of a high speed infrared camera with periodic electrical energy. The name "lock-in" comes from this synchronization mechanism. Sources of cyclic electrical energy include high-voltage amplifiers, bipolar power supplies, and pulsed power supplies. In addition to electrical energy, ultrasound, microwaves, flash lamps, lasers, physical forces such as bending, etc. may be used that lead to heat load on the inspected object. This technology is helpful for product failure analysis and nondestructive testing, such as potential defect analysis, thermal design, and battery thermal analysis.

Principles of Lock-in Thermography

Periodic electrical energy, such as high voltage, input to the inspected object is partially reflected when it encounters areas of heterogeneous thermal properties, such as delamination and inclusions. The reflected area interferes with the input pulse, creating an interference pattern of localized surface temperatures. This thermal reaction is periodically captured by an infrared camera, and temperature changes are extracted and analyzed using the lock-in method. Detects slight temperature changes by improving the signal-to-noise ratio using the lock-in method. By analyzing the phase shift and amplitude of the thermal wave, lock-in thermography derives information about the internal structure of the inspected object, including defects such as cracks, delaminations, cavities, and other sub-surface anomalies. For example, by adjusting the delay time of synchronization, the depth of the heat source and the problem area can be better defined.

Lock-in thermography is used in a variety of industries, including electronics, aerospace, automotive, and materials science.

- Electronics: Semiconductor devices, Short-circuits in electronic components, Printed circuit boards (PCBs), Current leakage, ESD defects, Gate oxide damage, Defect detection in transistors and other components, Solar cells, Dielectric breakdown, Whiskers

- Aerospace: Turbine blades, internal defect inspection of critical components such as composite structures

- Automotive: Failure evaluation of components such as batteries, motors, and electronic control units, battery thermal management for electric vehicles

- Thermal design and analysis: product defect analysis, thermal design and thermal analysis of components such as batteries and printed circuit boards (PCBs)

Recommended products

Matsusada Precision produces high-speed and high-voltage amplifiers for lock-in thermography.