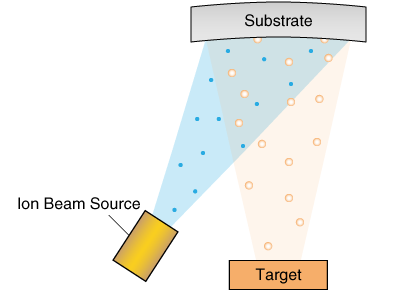

Ion beam deposition is the process of producing an ion beam as a thin film material at the ion source and accelerating to form a thin film. Typically used cluster-ion beam deposition produces excellent films with good crystalline properties.

Clusters are lumps of many atoms or molecules, and particularly when the atoms and molecules are gases, they are called gas clusters. The gas cluster is created using a high-pressure material gas by blowing it into a vacuum through a narrow, trumpet-shaped tube or a nozzle. The generated clusters are ionized with the electron impact method.

In this method, the high-speed electrons hit the cluster, and the electrons are bounced off the cluster, which makes the cluster positively charged. An electric field is applied to the ionized clusters and they are hit against the sample. It is used for processing and reforming.

Power supplies which are a core product of the ion beam deposition are available in a wide lineup of Matsusada Precision to meet applications like ion beam acceleration, extraction, suppression, deflection, grid and neutralization.