"Matsusada Precision was the only company that offered a high-voltage power supply that could precisely adjust the voltage required for flying car experiments."

Case Study: Nozaki Laboratory, Department of System Design Engineering, Faculty of Science and Technology, Keio University

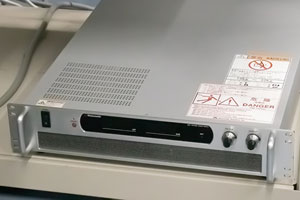

The Nozaki Laboratory, Department of System Design Engineering, Faculty of Science and Technology, Keio University, has adopted Matsusada Precision's high-voltage power supplies HAR series (AU series) as they work to establish a new propulsion principle using high voltage phenomena and build an experimental vehicle to realize a quiet, high-speed "Flying Car" without propellers powered by ion wind. The high-voltage power supply "HAR series (AU series) " from Matsusada Precision has been adopted. We asked him about the details.

"Nozaki Laboratory" controls the flow of power and creates new systems.

Please introduce Nozaki Laboratory.

Our laboratory conducts research on electric airplanes, non-contact power transfer, sensing technology, artificial intelligence, medical robots, etc., with power electronics, control engineering, and robotics as fundamental studies.

Specific research themes include the development of an "Electric Flying Car," which aims to realize a silent, high-speed "Flying Car" without a propeller; research on "Wireless Power Transfer" using a magnetic resonance method that utilizes the electrical resonance of the transmitting and receiving coils; research on "Contact Force Control" to realize flexible control so that robots do not hurt people when they come in contact with them; research on "Multifunctional Sensors" to enable robots to manipulate various objects; and research on "Sensorless Motor Control" to drive motors by estimating angles based on current values and mathematical models. In the field of surgery, our research covers a wide range of areas, including the development of "Medical Robots" to support remote-operated surgery, research on the detection of bone penetration in dental implant surgery, and the "Control of Dental Implant Drill" at the time of penetration. We are also working on the development of devices with a variety of functions.

Department of System Design Engineering

Associate Professor Takahiro Nozaki, Ph.D.

The motto of the lab is "Memories for the University! Leave your footprints in the world!" and we hope that our students will enjoy their research and bond with their fellow students, not to mention learn the methodology of system design consisting of modeling, analysis, and synthesis, and that they will have a fulfilling laboratory life, achieving world-class results.

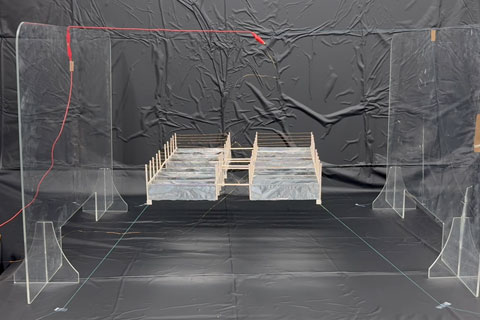

[Usage situation] The high-voltage power supply used in the development of "Flying Cars."

Please tell us about the studies you are conducting with the HAR series (AU series).

We are working on establishing new propulsion principles using high voltage, such as ion wind and plasma jets, and building experimental aircraft.

The ionic wind is a flow of air produced when voltage is applied between electrodes, and ionized molecules are accelerated by the electric field. Because it does not require fast-moving moving parts like a propeller, it is expected to be a quiet and robust propulsion mechanism for practical use.

Currently, the HAR series (AU series) is used as a power supply to apply a voltage of approximately 20kV to 40kV between flat sheets of aluminum foil. For voltage control, we have developed an original control program that automatically changes the voltage by remote control, and we are investigating the optimal shape of the voltage electrodes, the distance between electrodes, and the best combination of voltages to generate stable ionic wind.

The higher the voltage, the stronger the ionic wind would be generated.

That is true, but as the voltage increases, the air will cause dielectric breakdown and short-circuit, so circuit, so it is necessary to examine the voltage at the very limit of what will not cause a short circuit.

[Reason for selection] Only Matsusada Precision's high-voltage power supplies allow fine voltage adjustment.

How did you come to introduce the HAR series (AU series)?

For our experiments, we needed a high-voltage power supply with finely adjustable voltage. We searched the Internet and contacted several other manufacturers, but Matsusada Precision's high-voltage power supply was the only product that allowed us to fine-tune the voltage adjustment.

Matsusada Precision's product models are extensive, and its chassis is compact. We were able to select the best voltage device for our experiment. It also has safety devices such as short-circuit protection for voltage, which we thought would make it safe for students to use.

How is the usability of the product?

As for ease of use, there are no particular difficulties. The product itself has been operating stably and has not broken down or malfunctioned, although it may be used in a somewhat aggressive manner since it is used for experiments. As a power supply unit, it is well made.

How was the support response from Matsusada Precision?

As for power supply devices, we do not set up complex systems, so if there is anything we need help understanding, we have them respond to us via e-mail or web conference. I may have some basic inquiries from students who use the power supply system, which may be bothersome, but I am glad to know that they are being well taken care of.

However, the notation in the instruction manual for the setup is technical, which I have no problem with, but students unfamiliar with it may find it a bit difficult.

[Expectations and requests] Thank you for your flexible and prompt response.

Please let us know if you have any requests or expectations for Matsusada Precision.

Unlike most companies, we are users who require a lot of time and effort, but the personnel at Matsusada Precision are flexible and quick to respond, which has helped us on many occasions and we are very grateful for their support. I look forward to the same response and support in the future.

Since we have established a relationship, I would be happy if we could utilize each other's technical capabilities and experience, promote joint research, and take on new challenges together.

Thank you for taking time out of your busy schedule to share your valuable stories.

Location: 3-14-1 Hiyoshi, Kohoku-ku, Yokohama City, Kanagawa Prefecture

- Date of interview: May 2024

- The department in charge listed is the organization's name at the time of the interview.

- Related words:

-

- Ion engine

- Ionic wind

- Plasma actuators

- Dielectric Barrier